Shot Peening

Home / Shot Peening / Torsion Bar Shot Peen System

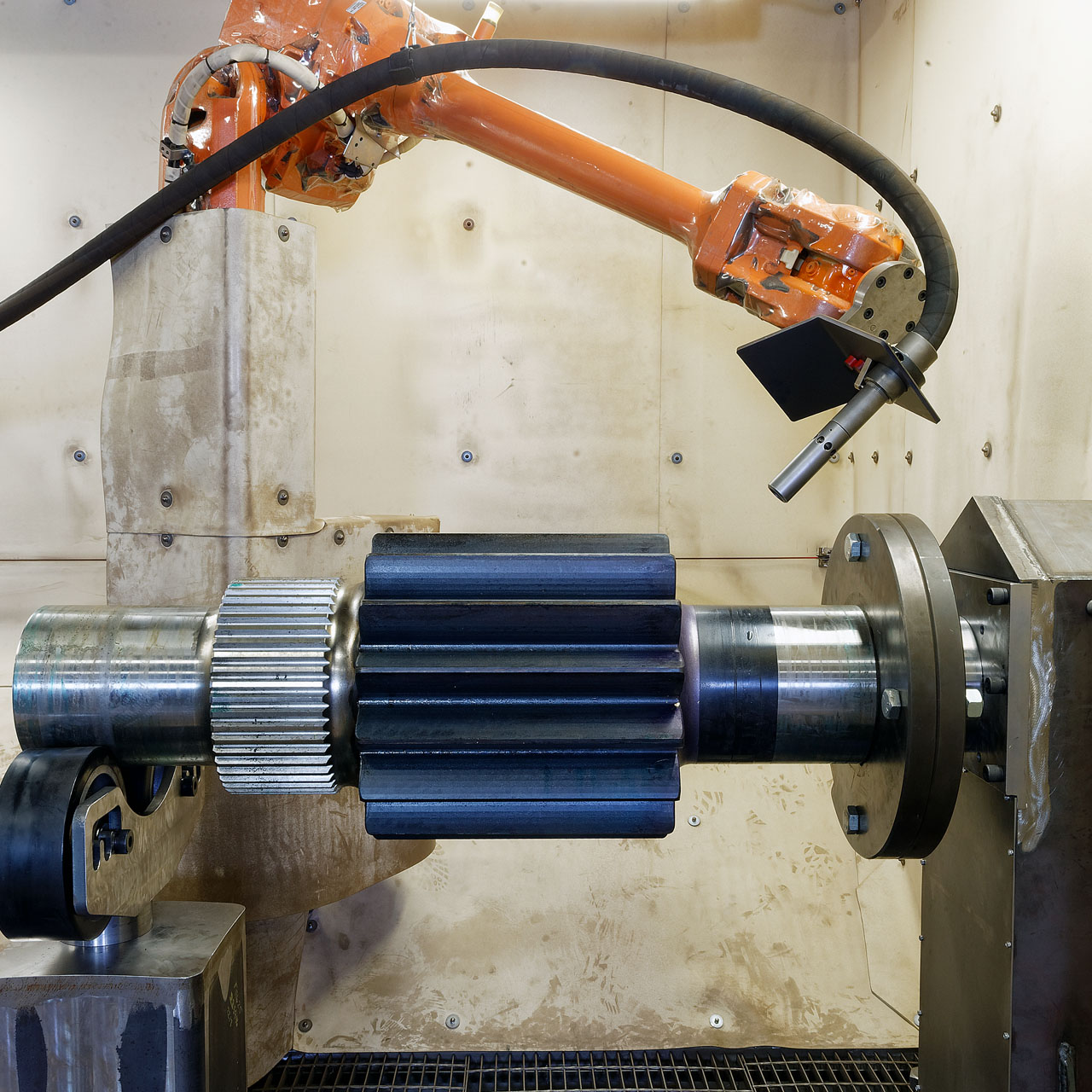

Torsion Bar Shot Peen System

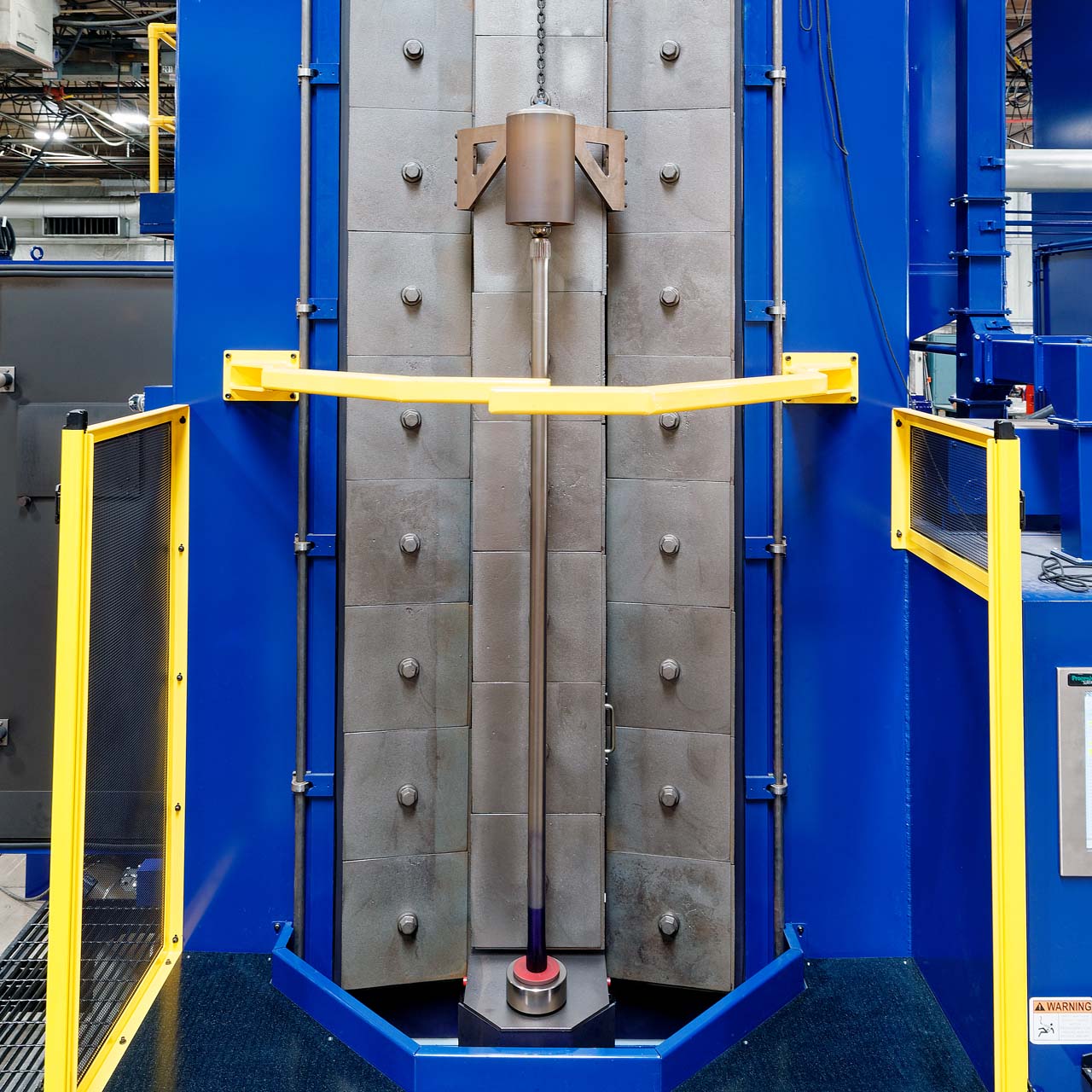

Pivoting door design to quickly load parts for high-intensity shot peening

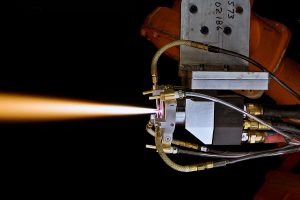

The operator can unload and load the next part while the machine peens a previously loaded part inside the process cabinet. The components require high-intensity A-strip peening using S170 and high-intensity C-strip peening using S330 and S550. The machine oscillates a line of 13 pressure delivery nozzles over the lengths of the bar. Both media sizes have a dedicated continuous flow pressure pot with closed-loop media flow controls on each of the 13 total blast hoses.

- Parts up to 90 inches long

- Two door-mounted programmable rotation spindles with adjustable tailstocks

- Two continuous-flow dual-stage pressure pot systems

- Internal armor plating for overspray protection

- Light curtains at load station for operator safety

- Quick-change media system switches between S330 and S550 with operator assistance

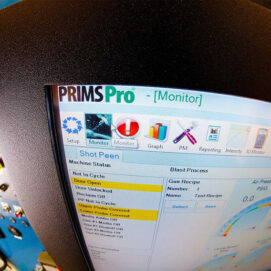

- PRIMS Pro® software provides ease of operation, continuous data collection, and report generation

- Quick-change media classifier screens (optional)

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

PRIMS Pro® Process Reporting and Integrated Monitoring System

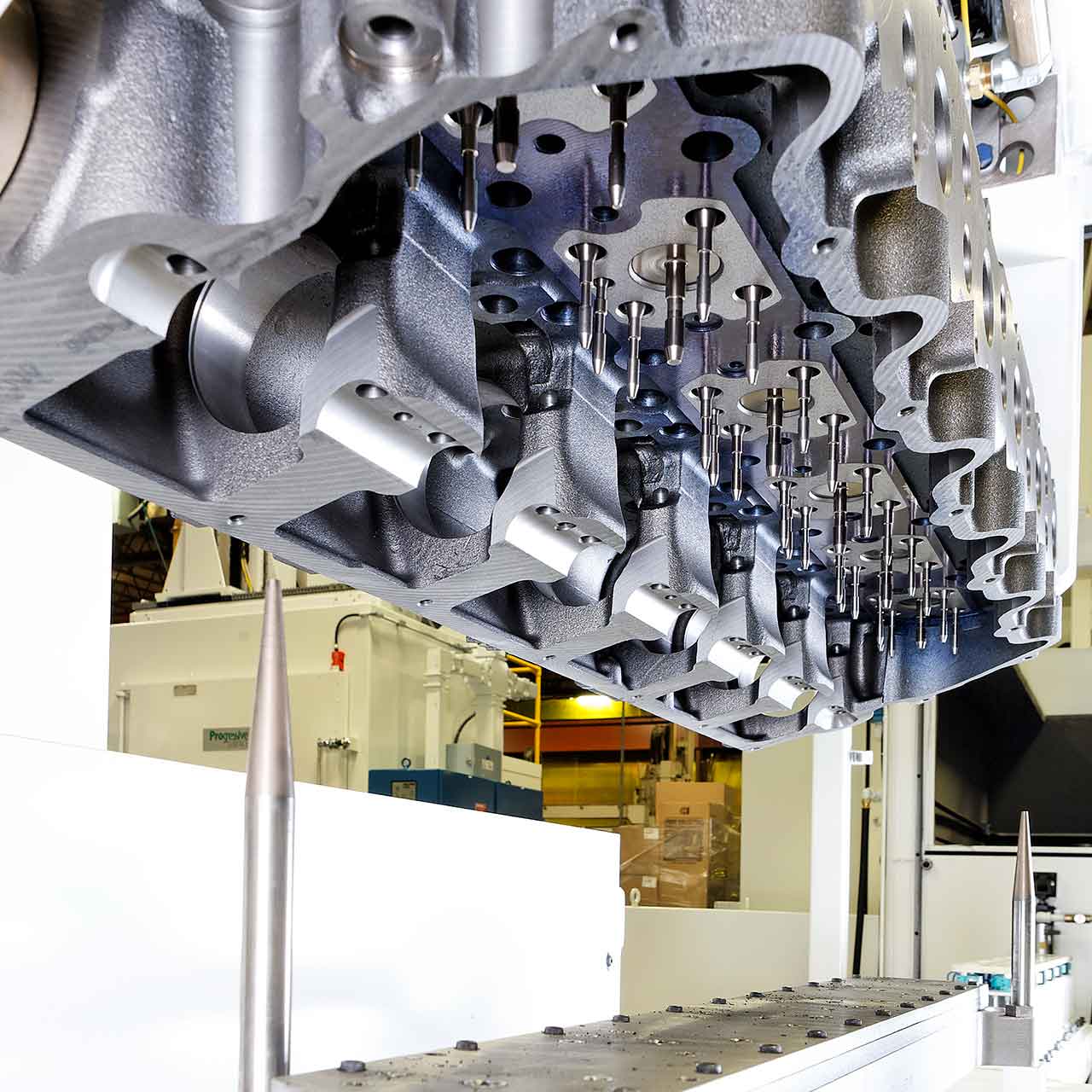

Automated Diesel Engine Head Shot Peen

Gear Peening for Large Mining Equipment