Shot Peening

Home / Shot Peening / Aircraft Engine Shaft Peening

Aircraft Engine Shaft Peening

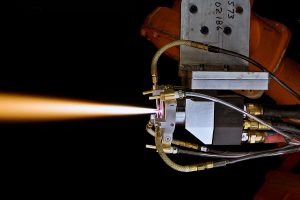

Large scale machine with robot on linear axis peens with six different shot sizes

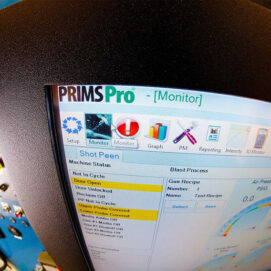

Need flexibility for peening a variety of applications? This machine can do it all. The large robot envelope and tilt table offer tremendous range of motion. Configured for long, complex shafts, this system does OD work, ID work, and indexing for flanges and holes and special geometry. The peening process is likewise flexible with programmable shot flow, air pressure, and shot sizes. PRIMS Pro® software manages it all with recipe selection, data logging, and network connectivity.

- Large cabinet with FANUC robot on linear axis hanging from ceiling

- Integral swing hoist

- Tilt turntable for vertical or horizontal applications

- Adjustable tailstock support tooling for processing shafts

- Side lance on linear axis for ID peening

- Rotary lance for hole peening

- Pressure pot system with MagnaValves® and closed loop air pressure control

- Changeover system for six different sizes of shot

- Vibratory screening system with quick-change option

- Automatic shot sampling system for quality checks

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

PRIMS Pro® Process Reporting and Integrated Monitoring System

Large Auto Door Peening System with Tool Changer

Robotic Shot Peen System