Thermal Spraying

Home / Thermal Spraying / Robotic Plasma Spray Booth with Powder and Suspension Material Delivery

Robotic Plasma Spray Booth with Powder and Suspension Material Delivery

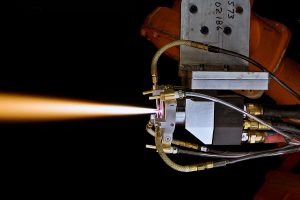

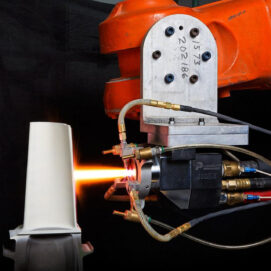

A truly Progressive plasma spray system with APS and SPS integration

This flexible robotic system is designed to apply thermal spray coatings to components using the 100HE Plasma torch. An ABB arm robot manipulates the spray nozzle around the part, which rests on a tilting rotating spindle. A well-ventilated, brightly lit acoustical enclosure isolates personnel from harmful noise, light, fumes, and dust. A dust collector and exhaust blower are provided to continually draw heat and dust from the process cabinet.

- Computer Integrated Thermal Spray (CITS) system to control all spray processes, manage part programs and recipes, control ventilation and safety systems, log data, and provide operator interface

- ABB 2600 robot with IRC5 controller offers a large working envelope for various geometries

- 250 rpm tilting rotating spindle with 500lb capacity

- Progressive Surface 100HE plasma torch

- Progressive LiquiFeederHE and Liquiedge water shroud

- Power supply & arc starter, 215,000 btu/hr heat exchanger

- Ladder and railing around the booth for locating some of the auxiliary components on the roof

- Progressive closed-loop gram rate controlled dry powder feeder

- Integrated part cooling module

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.