Thermal Spraying

Home / Thermal Spraying / Hydraulic Rod Grit Blast and HVOF Spray

Hydraulic Rod Grit Blast and HVOF Spray

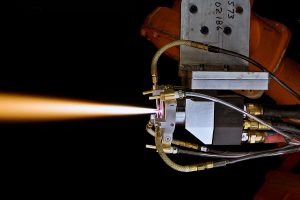

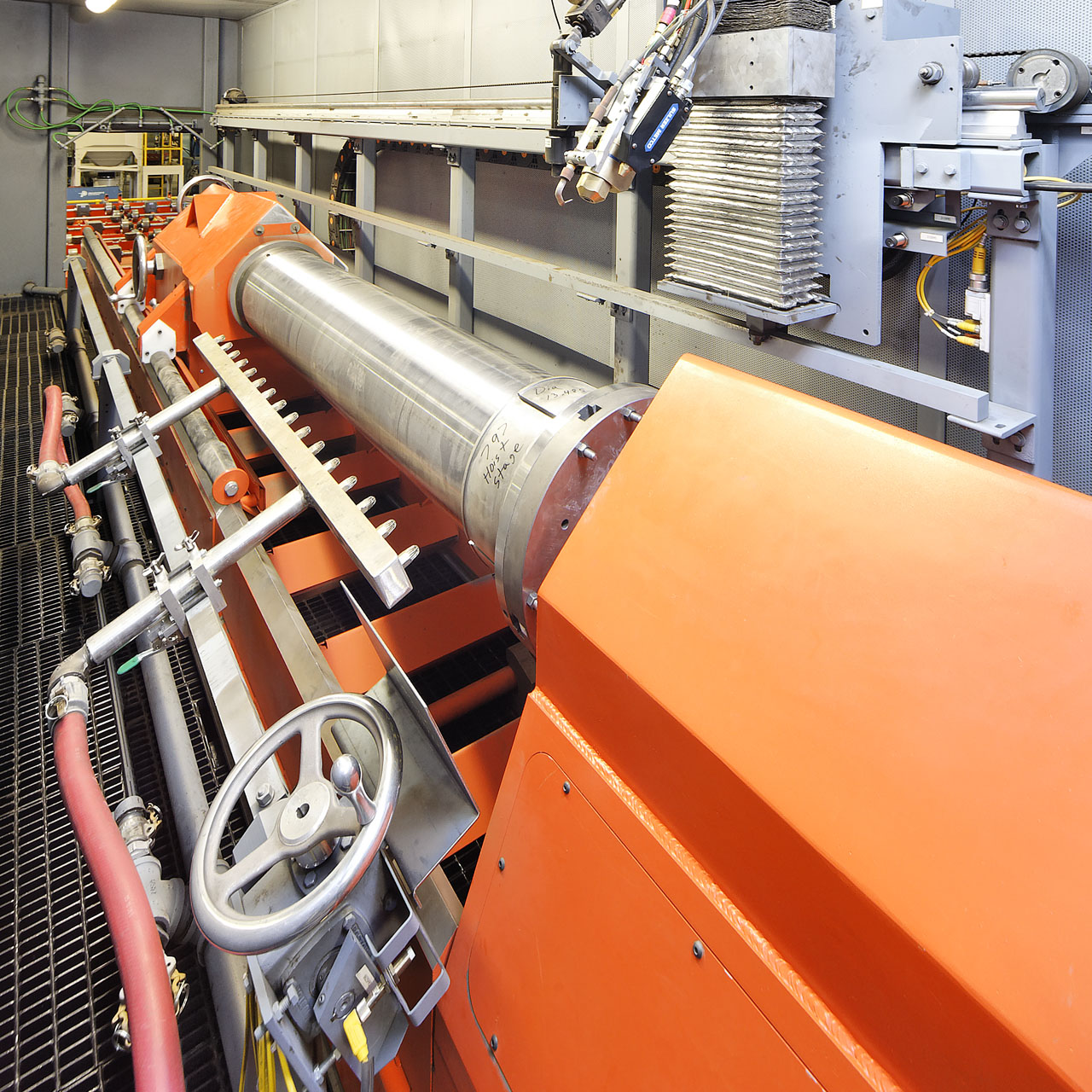

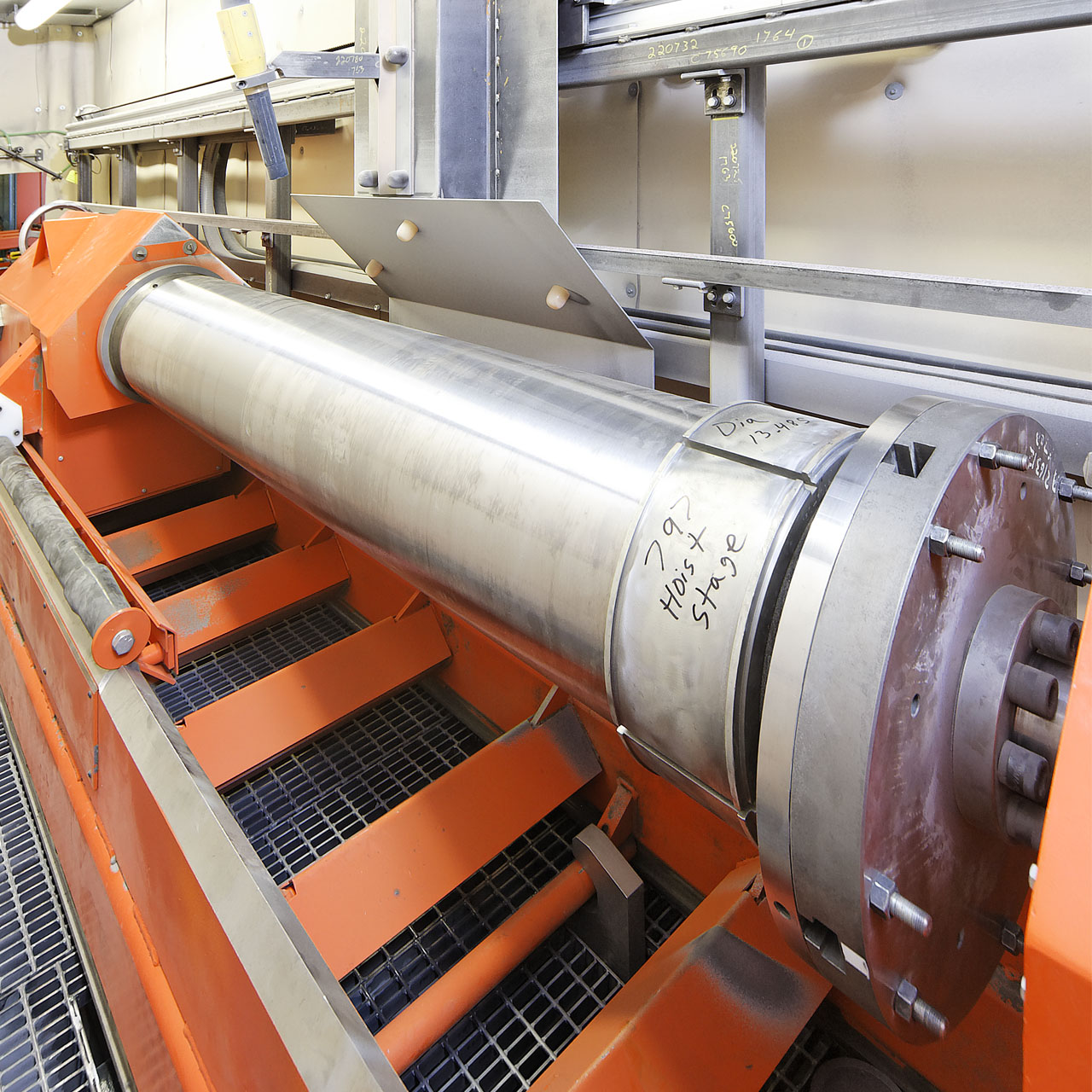

Parts on special lathe move to 2-axis systems for grit blast operation and HVOF coating operation

This integrated coating system is designed to apply hard-wear coatings on hydraulic cylinder rods or other components up to 12 feet (3.66 m) long using the HVOF thermal spray process. Parts are loaded outside the machine onto the lathe fixture. The fixture shuttles first into a grit blast booth, and then into the spray booth. The coating process is completely controlled inside the acoustical enclosure.

- Part loading and setup occur outside the machine

- Optional second lathe fixture allows part loading concurrent with the coating operation

- Programmable and recipe-controlled part RPM, coating gun spray distance, and feed rate

- Grit reclaim and screening system for consistent pre coating surface finish

- Cooling air manifold maintains maximum part temperature

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

CITS Pro® Computer Integrated Thermal Spray Systems

Large Crank Shaft HVOF Coating System