Waterjet Cleaning

Home / Waterjet Cleaning / Large Diameter Ultra High Pressure Waterjet Stripping System

Large Diameter Ultra High Pressure Waterjet Stripping System

Sliding automatic double doors save on floor space

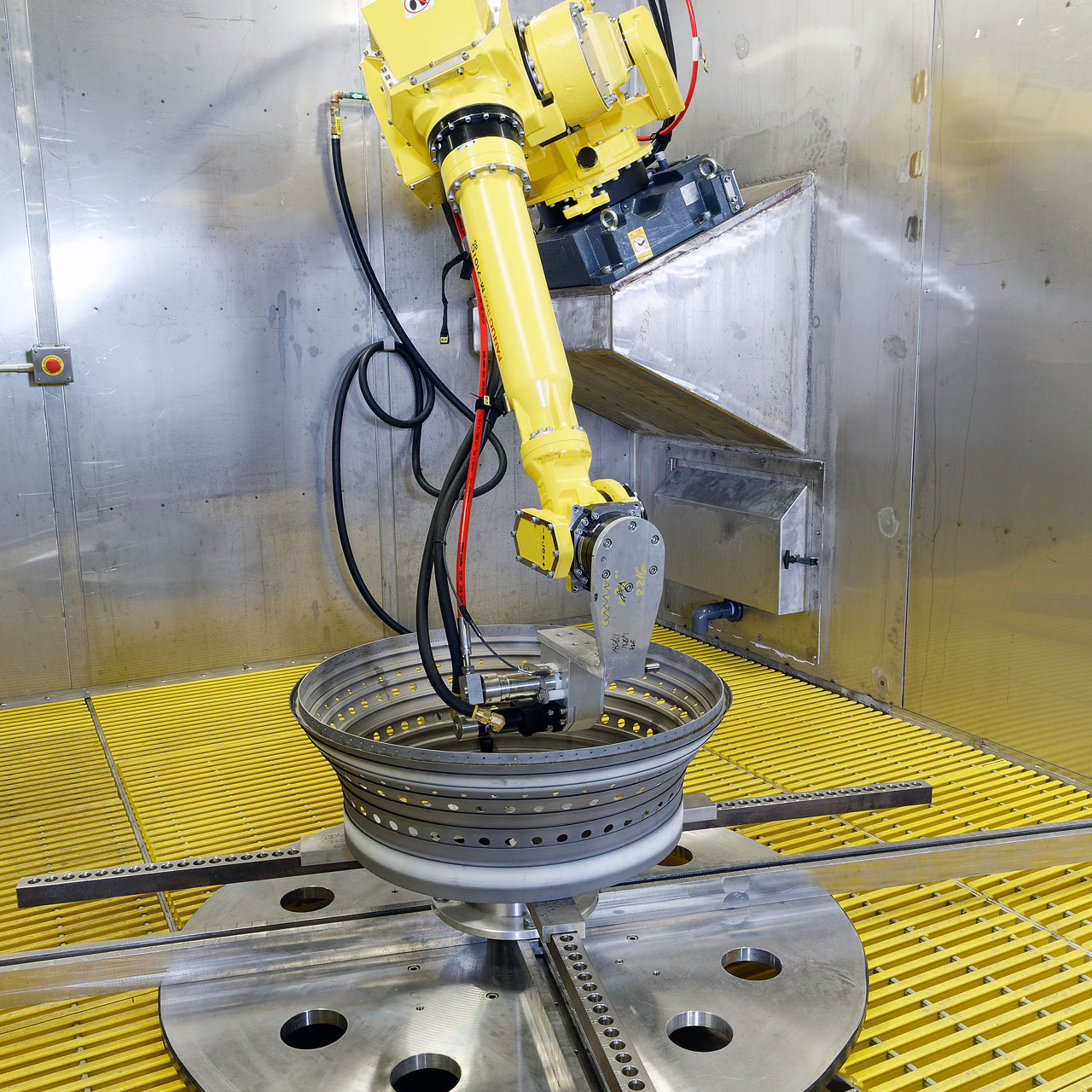

This system is designed to remove coatings from aircraft engine components up to 101″ (2.5m) diameter and 80″ (2m) tall. It offers 7-axes of robotically controlled coordinated waterjet cleaning motion. Nozzle motions are achieved using a side wall mounted Fanuc 710i articulated arm robot to allow robot arm access to clean internal surface of the component. Various Ultra High Pressure pump options available to fit your application and productivity requirements.

- The Fanuc articulated arm robot wall mounted to aid in accessing interior of components to be processed

- Laser nozzle verification sensor

- Aux Axis Spindle controlled by robot control for continuous spinning and coordinated part movement with robot nozzle movement.

- Automatic Sliding work door

- Cabinet mounted monorail hoist configurations can be offered to service the part load area.

- Stainless steel part centering and holding fixture

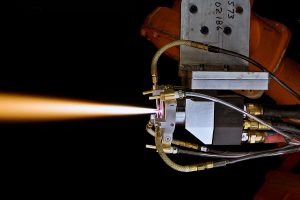

- High output 60,000 psi intensifier pump with high speed nozzle rotation for uniform, efficient coating removal with minimal substrate damage

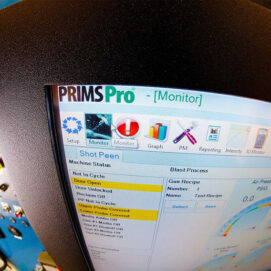

- PRIMS operator interface software streamlines part programming and reduces operator errors

- Predictive machine monitoring aids in preventative maintenance

- Closed loop water filtration

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

PRIMS Pro® Process Reporting and Integrated Monitoring System

48″ Diameter Ultra High Pressure Waterjet Stripping System

80″ Diameter Ultra High Pressure Waterjet Stripping System