Waterjet Cleaning

Home / Waterjet Cleaning / Waterjet Investment Casting Shell Removal

Waterjet Investment Casting Shell Removal

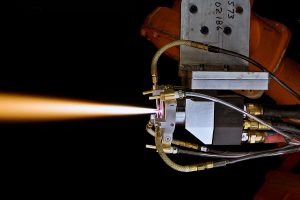

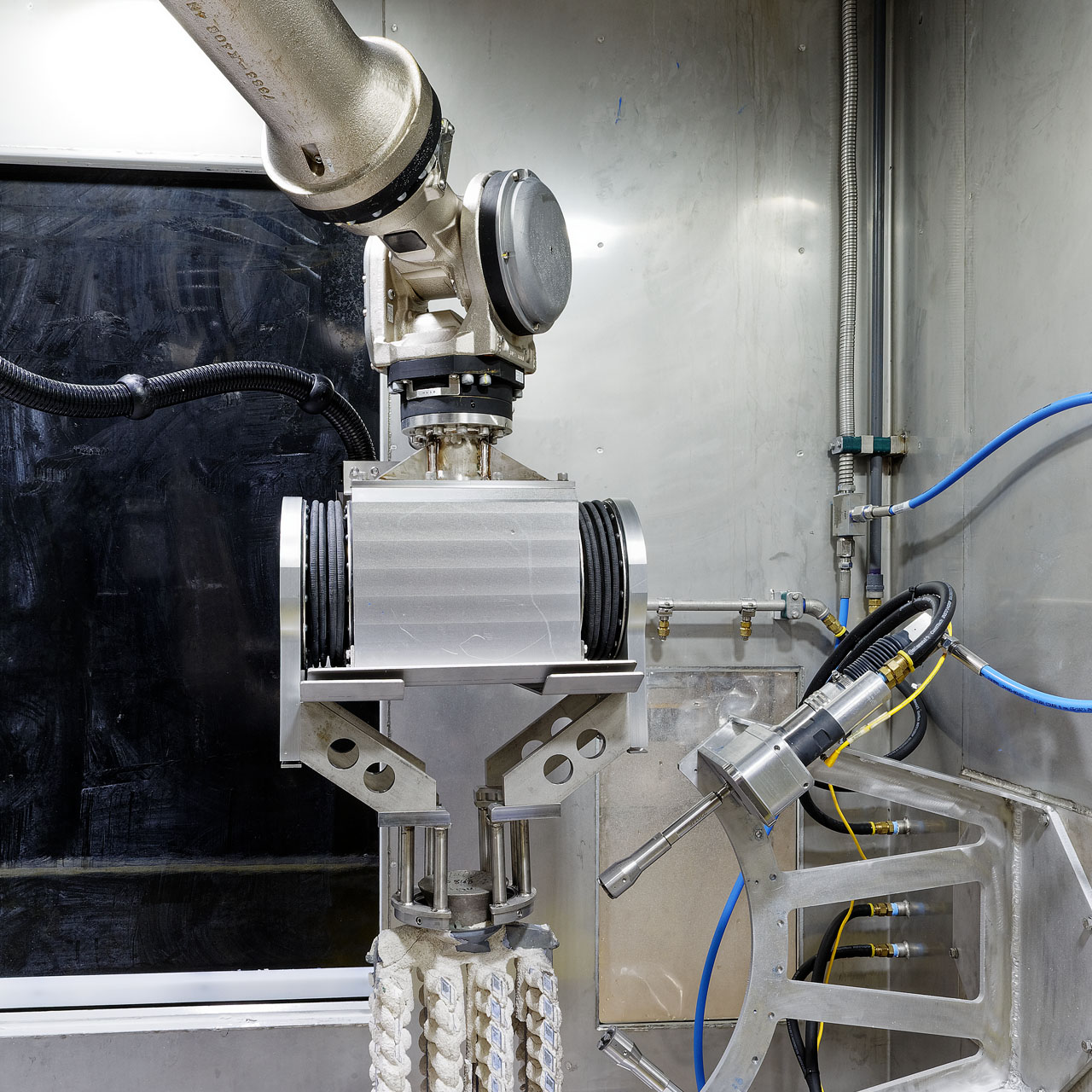

Large robot handles part clusters in/out of machine, and articulates in front of rotating waterjet nozzles

This waterjet machine removes ceramic shell material from clusters of medical or aerospace components after casting.. First, a large robot and gripper reaches through the front door to grab a cluster of parts. The robot then manipulates the cluster in front of waterjet nozzles. All ceramic debris is collected in hoppers within the machine.

- Stainless steel acoustical enclosure contains noise and water

- Dual rotating nozzles provide coverage into complex cluster geometry

- Hoppers under the machine are easily removed for dumping of debris

- NLB high performance pump provides 15 gpm at 10k psi

- Water filtration system options are available

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

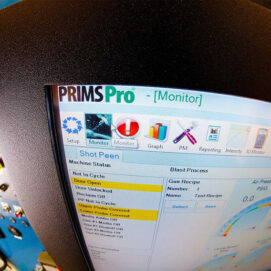

PRIMS Pro® Process Reporting and Integrated Monitoring System

Waterjet Cleaning System for Solid Rocket Booster Overhaul