Custom Automation

Home / Custom Automation / Multi-Station Tube Shot Blasting with Robotic Handoff

Multi-Station Tube Shot Blasting with Robotic Handoff

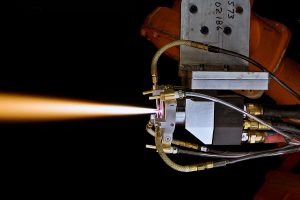

ID blasting with horizontal lance and OD blasting with nozzles on automotive forgings

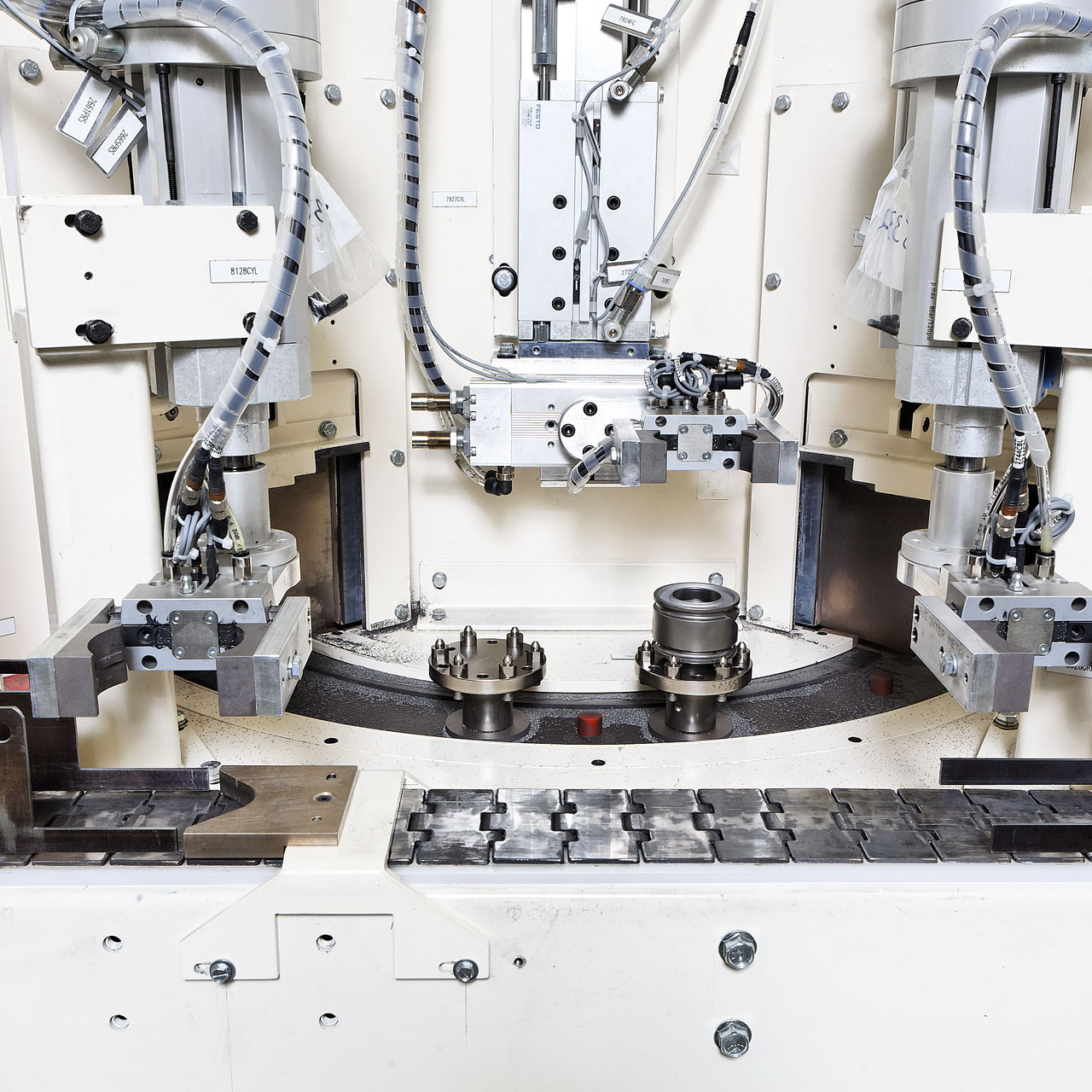

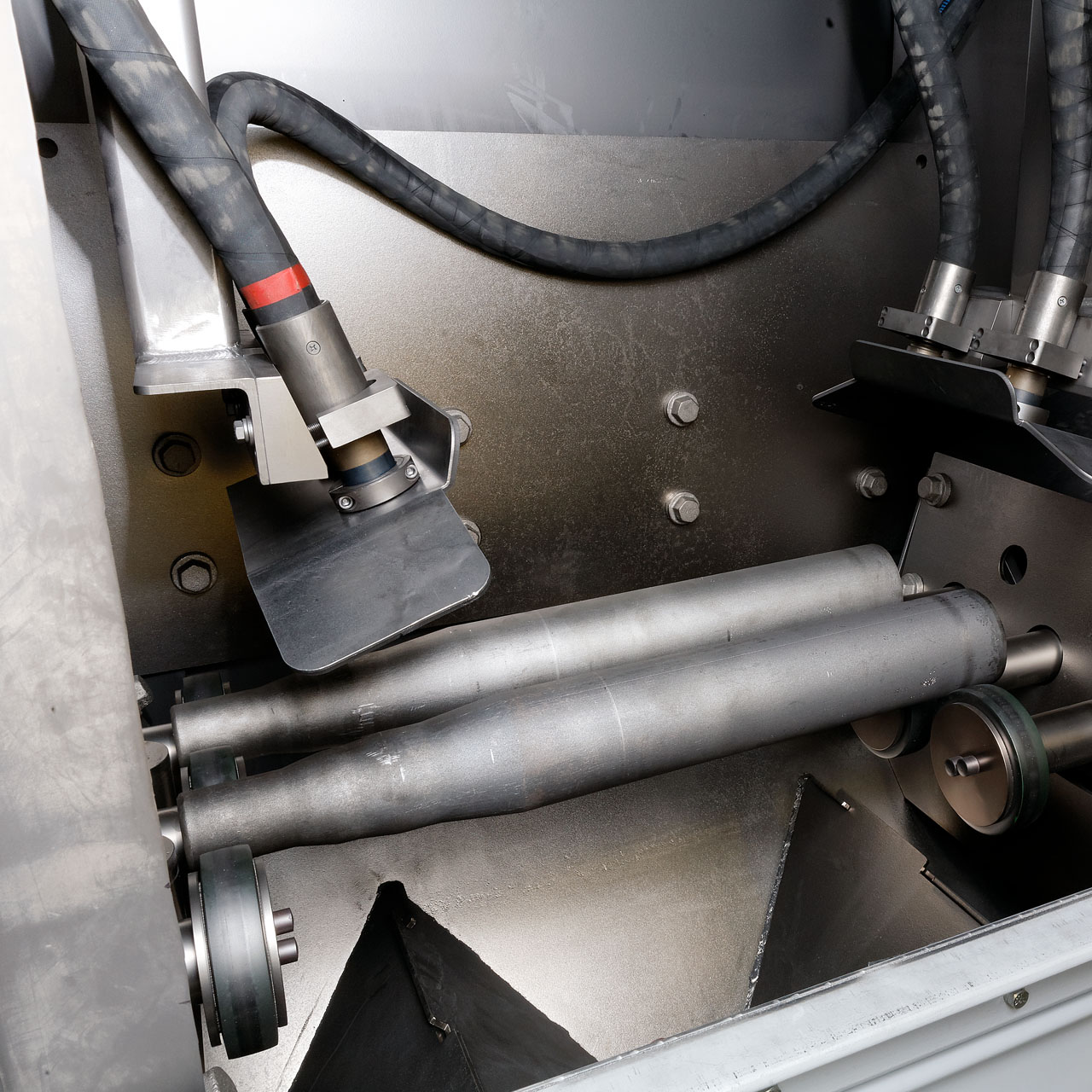

After forging and heat treating, heavy-duty axle tubes need a shot blast operation to remove graphite and scale. This custom-designed shot blast machine utilizes nozzles on the tube OD and lances on the ID. Programmability of nozzle/lance movements is provided to accommodate different part diameters and lengths. Three robots are fully integrated for machine loading, unloading, and handling down the production line.

- Extensive use of manganese steel armor inside the blast cabinet

- Dual work doors for rapid pass through load and unload

- Urethane rollers for rotation of tubes inside blast cabinet

- OD nozzle movement is programmable independent of ID lance

- Pressure pot system provides efficient, continuous delivery of shot

- Dust collector is powered for pneumatic reclaim of shot

- Panelview HMI for shot blast operation

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Gantry Area Sheet and Waste Handler for Laser Bed Tending

ABB Arm and Rail Sheet Organizer for Laser Bed Tending

Automated Sheet Handler for Large Hydraulic Press