Custom Automation

Home / Custom Automation / Automated Sheet Stacker for Laser Bed Tending

Automated Sheet Stacker for Laser Bed Tending

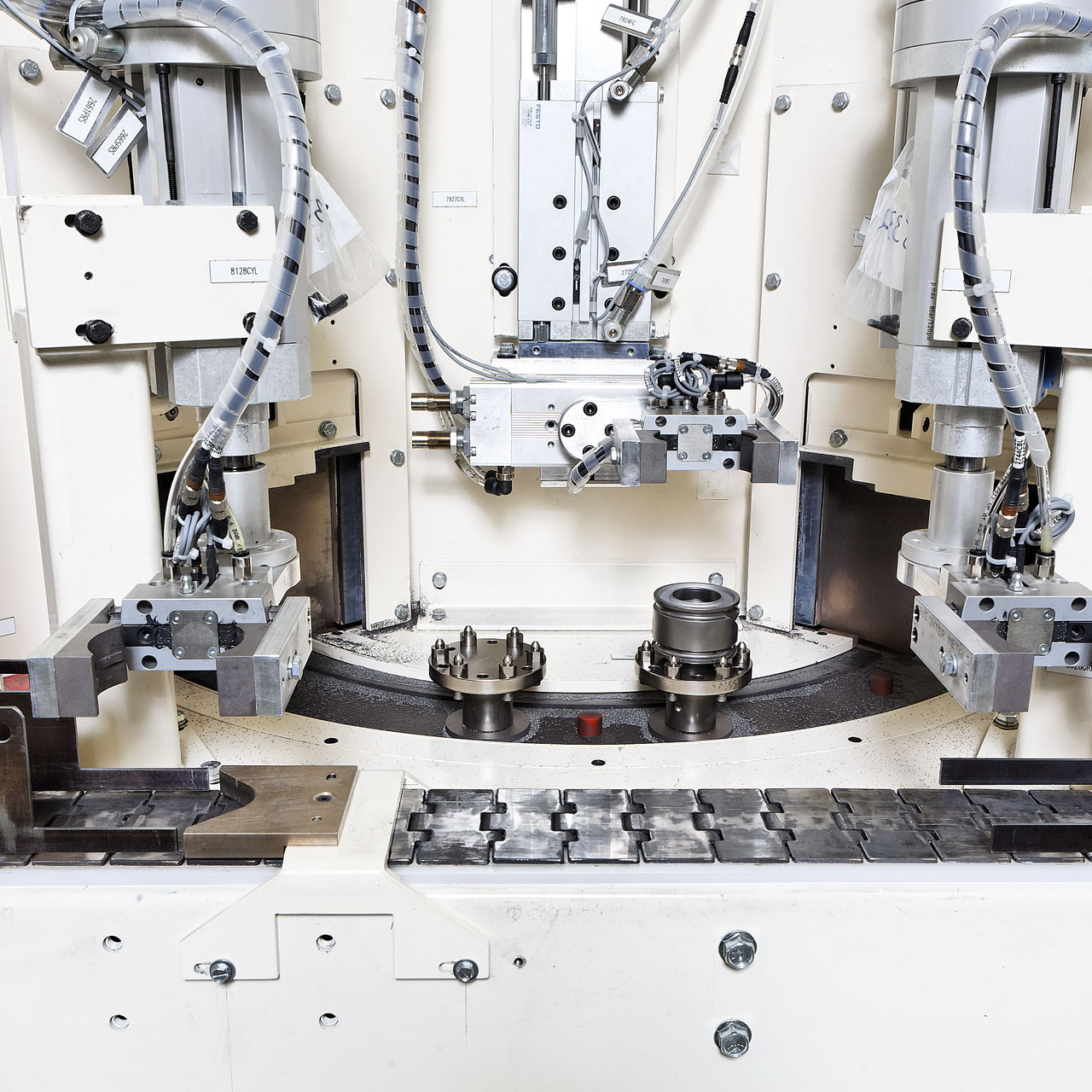

Up to eight drawers for sheet material storage and loading onto laser bed

Metal cutting machinery like lasers and turret punch presses can be operated “hands off” when integrated with a Progressive material storage tower and sheet handling system. This system straddles the load station and delivers one sheet of raw material at a time. A rear elevator retrieves and stores up to 8 pallets of material. The front elevator handles either the finished product pallet or the scrap pallet. Integral suction cup system and unload “fork” system allow the metal cutting machines to run uninterrupted.

- Parts up to 60 inches in diameter and 60 inches tall

- Four-drawer or eight-drawer storage tower

- 6,600 lbs of material per pallet

- Suction cup loader with single sheet detection

- Fork system to unload entire table

- Safety fencing and door interlocks

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Multi-Station Tube Shot Blasting with Robotic Handoff

High Volume Grit and Shot Blast Line

Gantry Area Sheet and Waste Handler for Laser Bed Tending