Process Services

Home / Process Services

Progressive Surface’s 60+ years of experience has provided us with the technical skills to meet your process and application development needs. Looking for a production source for your parts? We have many highly efficient systems to provide shot peening, grit blasting, waterjet stripping, or thermal spray coating services that meet specification requirements with quick turn-around times. Progressive Surface is ITAR registered and has an approved FAA drug and alcohol testing program.

Get a quote for process services

+1.800.968.0871 toll-free

+1.616.957.0871 phone

High-pressure waterjet stripping

Using multiple robotic systems with closed-loop process control and reporting for stripping turbine engine components, we can process parts up to 53″ diameter by 30″ tall.

We have experience with all major turbine engine OEM waterjet repairs. Our equipment and process controls meet the requirements of GE SPM 70-23-23, CFM SPM 70-23-70, PW SPOP 322, and Rolls Royce Standard Practice. Our focus is thermal spray coating removal from aircraft engine and industrial gas turbine components.

ITAR registration and our approved FAA drug and alcohol testing program allow us to process military and flight critical components.

Shot peening

Progressive employs multiple robotic shot peening systems with closed loop process controls and reporting for the peening of critical or complex part geometries including lance peening holes and IDs. Maximum part capacity is 48″ (1.2 m) diameter, 48″ (1.2 m) tall. These systems meet the requirements of Nadcap, AMS 2432 and the most stringent OEM critical parts peening specifications

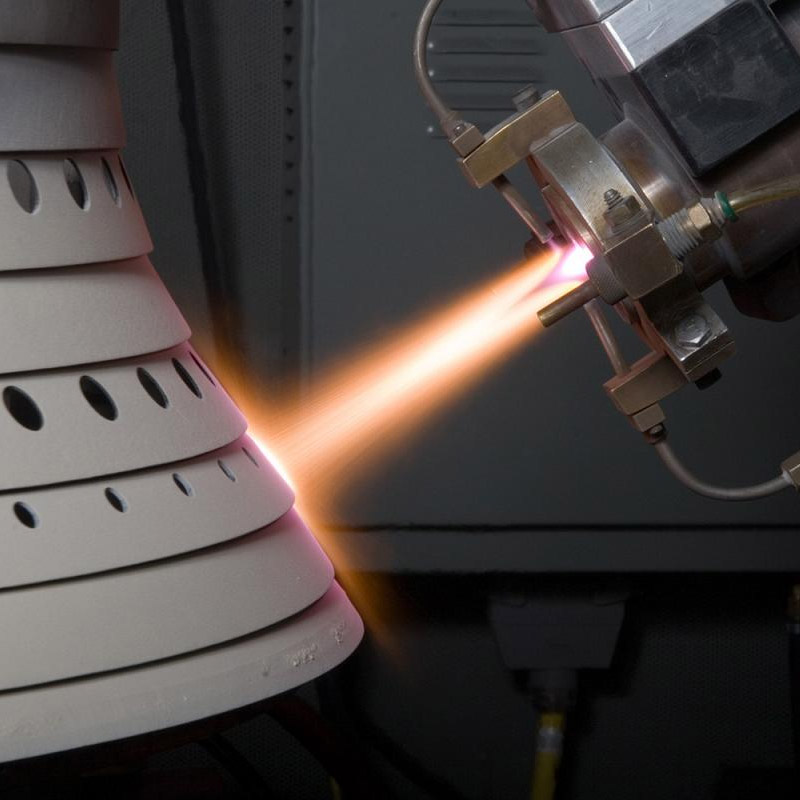

Thermal spray coating

With over 40 years of experience with thermal spray processes and multiple high volume production systems, we can provide coating of several critical advanced technology parts.

Application/process development

Looking for application or process development help with your Progressive system? Our engineers use our in-house systems to conduct application development, demonstrate it for you, and then transition it to your facility’s Progressive system. We also offer part-holding fixturing and Almen tooling designed to meet the harsh requirements of shot peening, grit blasting, waterjet cleaning or thermal spray coating. Applying decades of materials and coating development experience, our experts can develop specialized coatings for use with today’s most advanced processes including suspension and solution plasma spray (SPS/SPPS).