The Spring edition of The Shot Peener is a wonderful place to showcase new beginnings. Following a long, cold and dark winter season, everyone looks forward to the spring when dormancy is replaced with renewed growth and optimism.

After five years of Research and Development at Progressive Surface and collaborative brainstorming with several key clients, we have chosen the spring of 2016 to introduce The Future of Shot Peening to the general peening population. This new age of shot peening is the solution to a quickly growing problem in the aerospace industry.

The Problem

Components for the newest generation of commercial aircraft engines—the LEAP and geared turbofan (GTF)—have very complex geometries, narrow tolerances and demanding surface treatment requirements. These components need a wide variety of shot peening tools and frequent peening nozzle and lance changes to access all of their surfaces.

Compounding the manufacturing challenge is the popularity of these quiet, fuel-efficient, and low-maintenance engines. The demand for the new engines will soon outpace manufacturing unless automation is adopted. The combined production rate of the 737 MAX and A320neo will reach 110 aircraft per month in 2018 and each aircraft will require two engines. The sales figures for these two aircraft models are now at nearly 8,000 confirmed orders. The LEAP and GTF are being placed on other popular aircraft models as well. Industry analysts are saying there is no end in sight for the demand of these two new engines.

The Solution

The answer to this opportunity is industrially hardened and process specific automation for the shot peening environment.

The shot peening industry will never be known as an “early adopter” of automation. This is not due to a lack of interest or desire, but rather an environmental issue. Shot peening has always been associated with very abrasive media, process dust and impact energy, making this industry a poor candidate for automation…that is, until now.

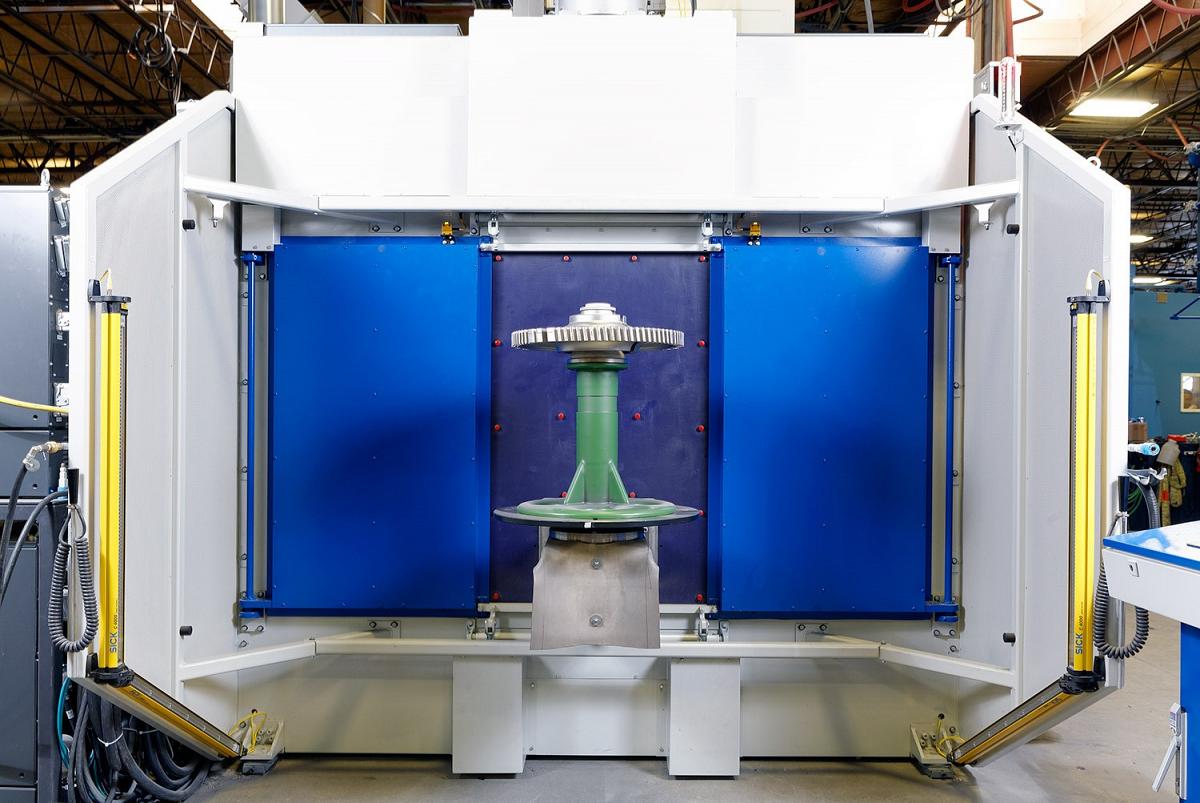

In response to industry demands, Progressive Surface has manufactured several fully automated shot peening systems. “Fully Automated” means robotic part loading and closed-loop parameter control and monitoring, but the game changer for shot peening automation is the “tool changer.”

Our new shot peening system can robotically change from a conventional nozzle to a rotary lance head. It also has the ability to change between different sizes (length, diameter) of conventional nozzles and process/part specific lance nozzles. The Progressive Surface Tool Changer uses acommon blast hose delivery system with a highly specialized nozzle/lance holder. This Tool Changer resembles and operates as seamlessly as the Tool Changers used globally in multi-axis machining centers.

Imagine shot peening a turbine disc or maybe a complex blisk. Conventional peening nozzles have always been adequate for easy line-of-sight surfaces, but the disc has blade slots and a variety of small bores that require a Rotating Lance nozzle. Additionally, the part has hidden areas in the main bore that need a non-rotating L-Shaped lance, requiring a nozzle change. Or maybe it’s the complex blades of a blisk that need to be peened without distortion, requiring a two-nozzle blisk tool.

If this describes your shot peening operation, then you’re no doubt familiar with stopping the process and entering the peening cabinet to change nozzles. Maybe you need to check the alignment of the new nozzle and, most likely, run an Almen strip test. All of the above steps create non-productive, non-revenue producing machine downtime. These actions also invite operator error to enter the equation.

The Progressive Surface automated tool changer is the game changer our industry has been seeking. The shot peening process and related industry is nearly 100 years old. I can’t help but wonder what Mr. Almen would think of the today’s shot peening industry—from its humble beginnings of manually grit blasting automotive valve springs to the peening of today’s complex aerospace components.

Speaking of the past and future, is the new Tool Changer our industry’s equivalent to Marty McFly’s Hoverboard? (Reference: Back to the Future II)

Two Key Features of the Intelligent Machine

Cabinet-Mounted Camera

The Progressive Surface Automated Cell illustrated in this article includes a cabinet-mounted camera interfaced directly to the two robot controllers. This is a valuable, errorproofing tool. The camera compares the part to be peened to the associated image stored in its part program. If the part loaded does not match the stored image’s information, the process will not start and the attending operator is given an alarm message. When the correct part is loaded, the camera compares the part orientation and automatically adjusts the robot off-sets to match the exact part position. This feature eliminates nozzle/part collisions and lance nozzle breakage.

The ShotMeter

The second Automation Plus feature is the ShotMeter. The ShotMeter is an optical sensor that accurately senses, measures and records the actual shot peening media velocity. For the system discussed in this article, the ShotMeter sensing head is located in the ceiling of the peening cabinet, extending for easy robot access and retracting when not in use. Once programmed, the robot will present the peening nozzle to the sensing head and the media velocity will be measured and compared to the part program requirements. After the velocity comparison is complete, the peening cycle can commence.

The media velocity is almost like a fingerprint—the blast hose diameter and length create unique media velocity with each different media flow and air pressure. Over time, the velocity slowly changes as the hose wears. The same is true for the blast nozzle. Virtually each and every nozzle type, length and internal diameter has a unique velocity with a given media flow and air pressure parameter when the nozzle is new. The media velocity is altered as the nozzle slowly wears. This Automation Plus feature provides very accurate monitoring of the peening process to the point where many users are creating new shot peening specifications that greatly extend the interval between Almen strip test runs.

Note: For now and the foreseeable future, Almen strips will still be used when setting up the initial peening programs and for machine verification.

The Future of Shot Peening is Now

Industry practitioners and experts alike agree there is a need and desire to automate and error-proof the process. Many naysayers have preached that the environment was too harsh and dirty to house cameras and tool-changers. Until now, all of this was true.

A new generation of Automated Shot Peening systems have been designed and proven in the field. Maybe for your application, automation starts with robotic or automated part loading. Maybe your requirements include in-process media changes to complete a part. Or, maybe your part geometry and closing tolerances need more surface-specific peening nozzles. In any of these examples, automation is the answer and with the exciting new generation of shot peening equipment, all is now possible.