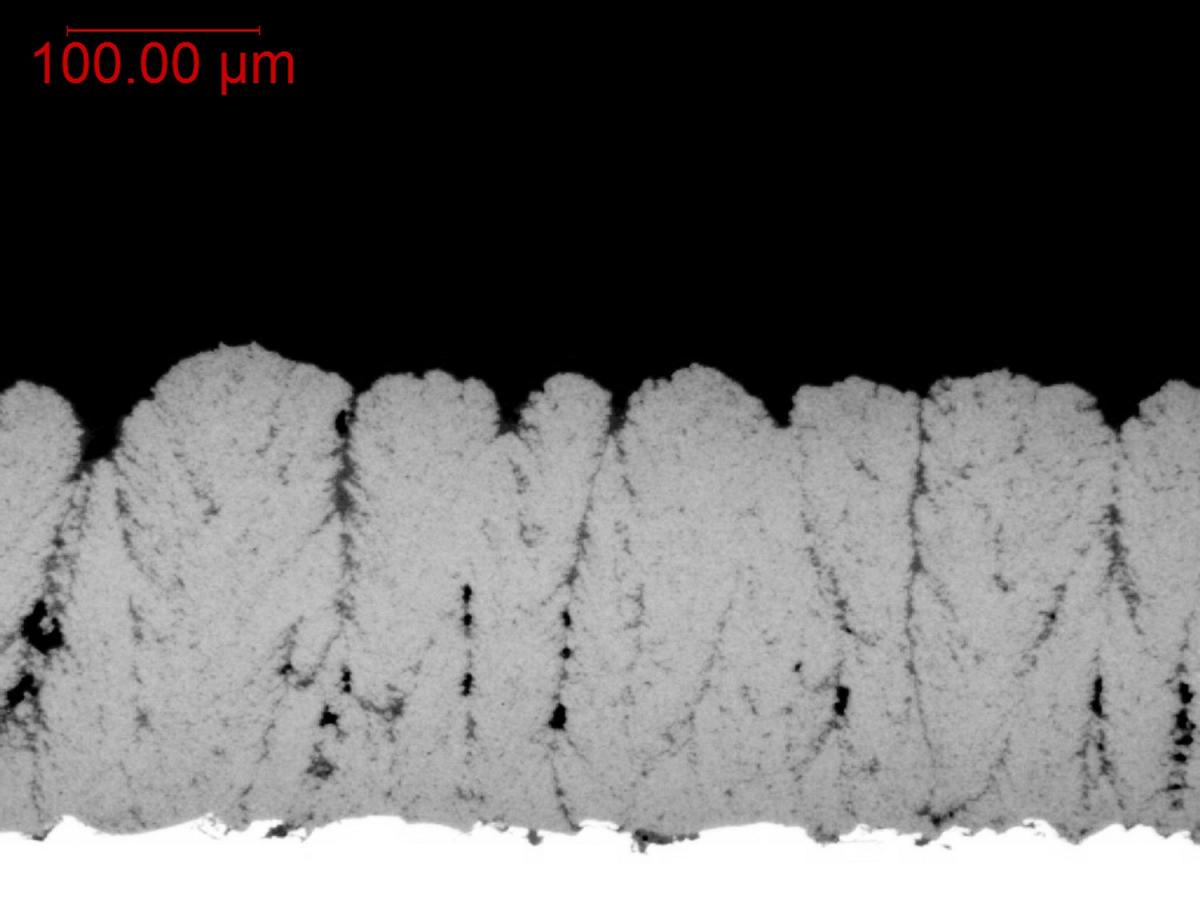

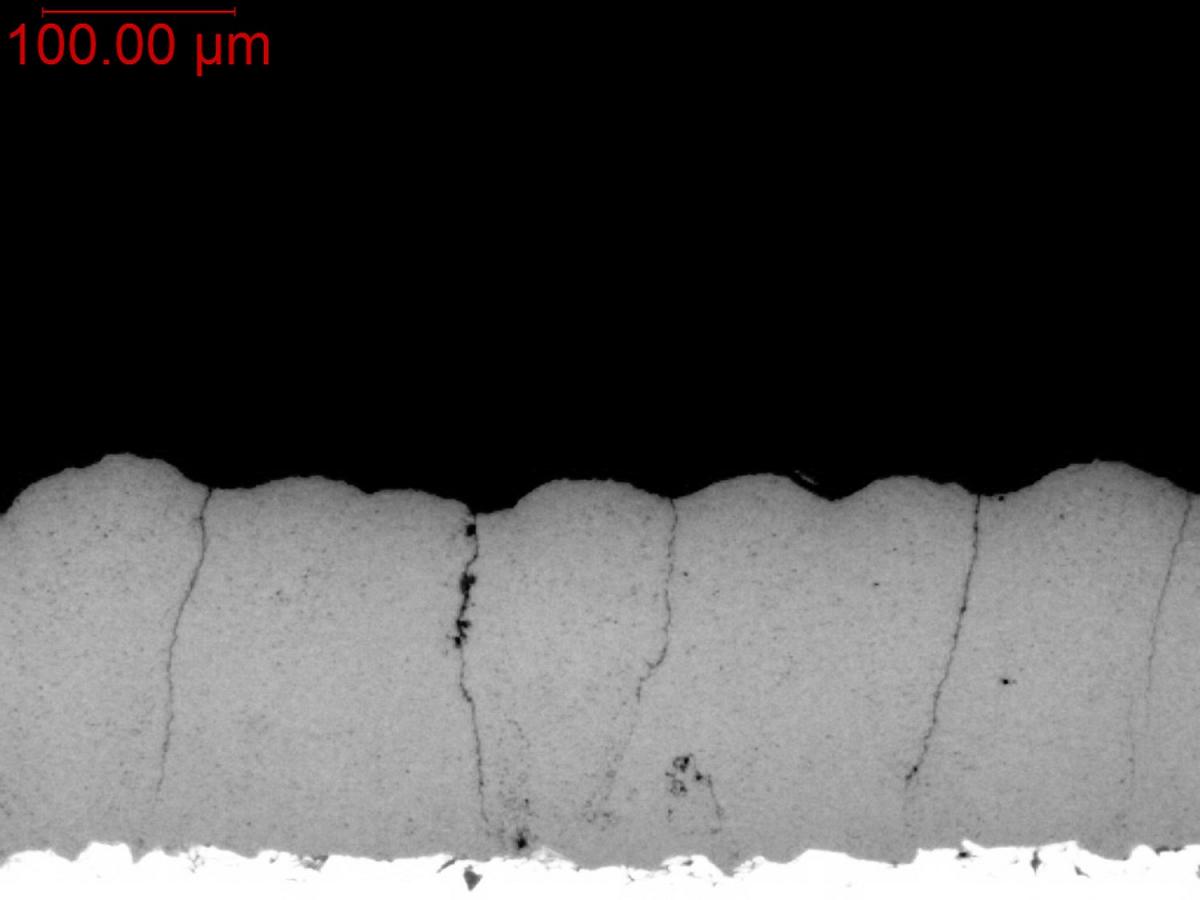

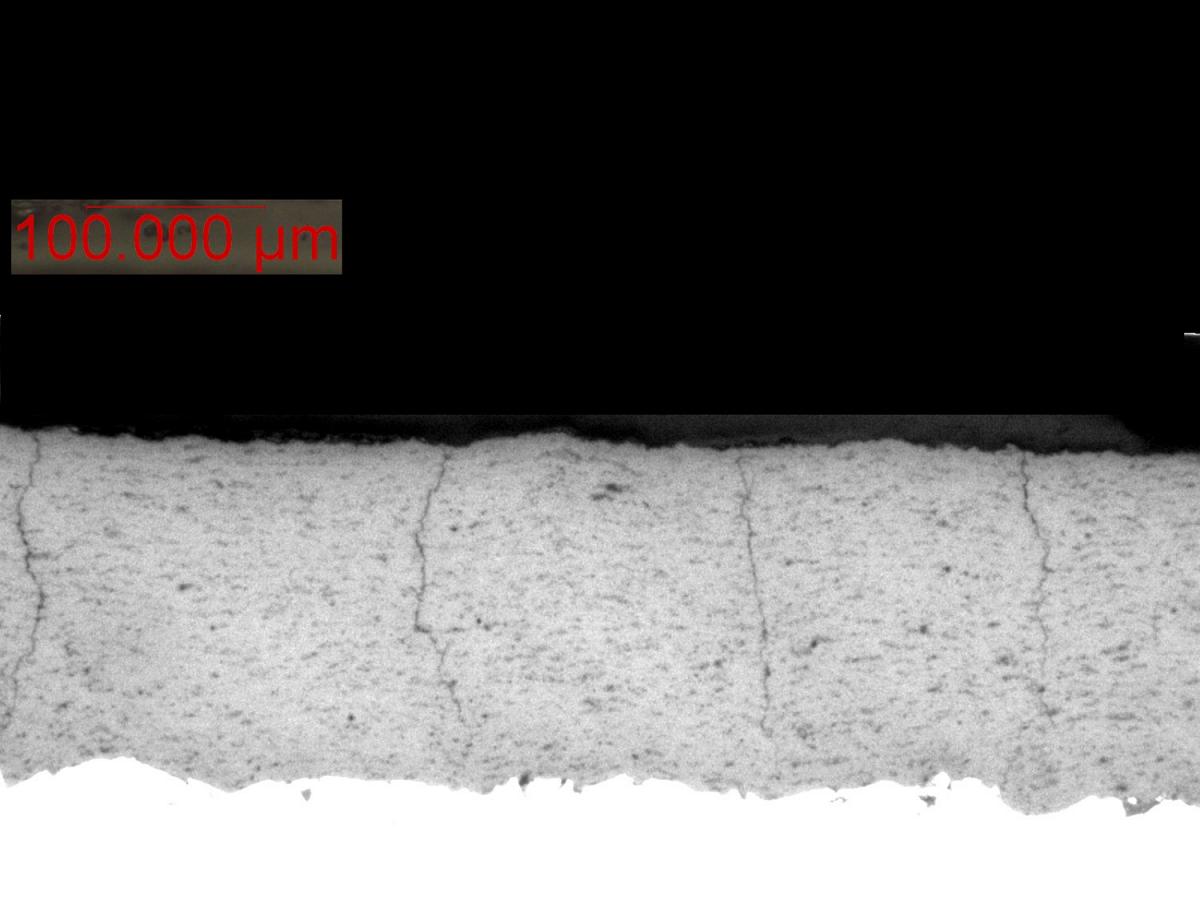

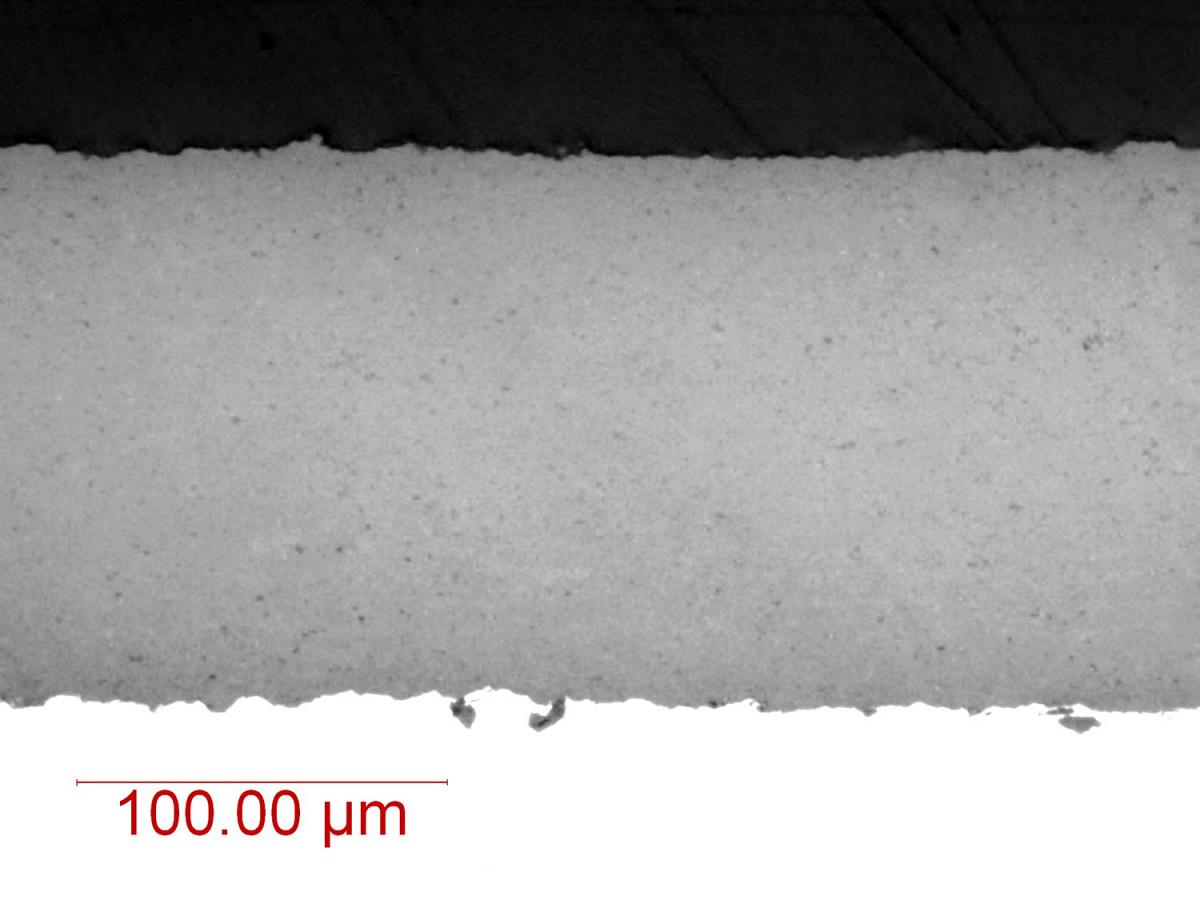

A new breed of nano-structured coatings are being developed around the suspension plasma spray (SPS) and solution precursor plasma spray (SPPS) processes. SPS and SPPS require more energy per deposited mass than conventional powder spraying because a liquid carrier must be vaporized before the plasma can interact with the coating material. The 100HE® is well equipped to meet this increased energy requirement through the use of high enthalpy gas mixtures (Ar-N2-H2 or Ar-N2-He) and operating powers up to 105 kW.

The small particle/droplet sizes within SPS and SPPS increase the sensitivity of the feedstock materials, and thus the microstructure, to changes in the plasma flow. The ternary gas mixtures and high arc voltages (>200 V) of the 100HE generate an extremely stable plasma, allowing for consistent feedstock injection and heating.

The performance characteristics of the 100HE have proven to yield a very effective and versatile SPS/SPPS platform that is capable of spraying coatings from 25 wt% solid suspensions and solutions (dissolved solid content) at flow rates of up to 90 ml/min with deposition efficiencies ranging from 50 – 80%. The micrographs shown provide an overview of the different SPS and SPPS coating structures that Progressive Surface has produced with the 100HE.