Custom Automation

Home / Custom Automation / Process Development Capabilities

Our unique combination of system engineering expertise, leading edge process development, and lifetime support, allow us to provide customers with the right solution to their processing needs.

Process Development Capabilities

Leverage our nearly 60 years of process and equipment design knowledge

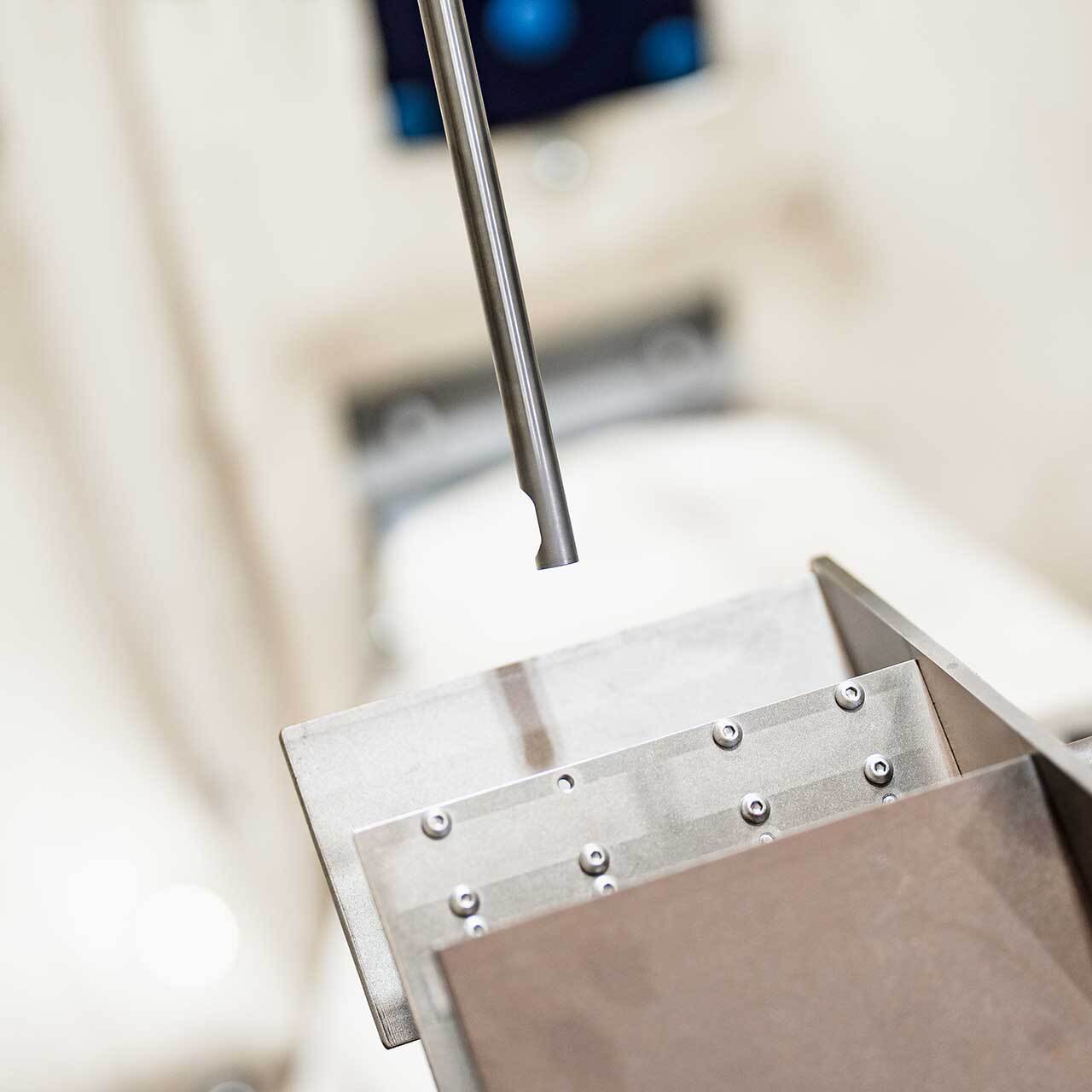

Tell us your goals for a new or existing product, and we’ll help you select the process and develop the parameters to reach them. Our in-house collection of robotic machines enables us to explore various methods and repeat the results for demonstration. We’ll also look at multiple fixturing methods to minimize part-handling steps and reduce production cycle times. Our final report will detail our various tests, the tradeoffs discovered, and the final parameters that achieved the goal.

- Free initial discovery service benefits both Progressive Surface and the customer

- Progressive estimates cycle times and suggests machine configurations to achieve throughput

- Recommends materials to resist wear in harsh process environments

- Provides considerations for manual and automated part loading and unloading

Related Machines

Double Robotic System to Etch Aircraft Engine Components

One robot loads and rotates the part, while a second manipulates the nozzle.

Read More

ABB Arm and Rail Sheet Organizer for Laser Bed Tending

Robot on rail selects material from 24 different drawers.

Read More

Walking Beam System for Abrasive Blast Long Tube Inside Diameters

High production surface etching uses the tube as the blast chamber.

Read More

Automated Sheet Handler for Large Hydraulic Press

Integrated gantry, conveyors, and feed system, all controlled by CNC.

Read More