Shot Peening

Home / Shot Peening / Our Application Expertise

Our unique combination of system engineering expertise, leading edge process development, and lifetime support, allow us to provide customers with the right solution to their processing needs.

Our Application Expertise

Creating custom solutions to match every customer’s needs

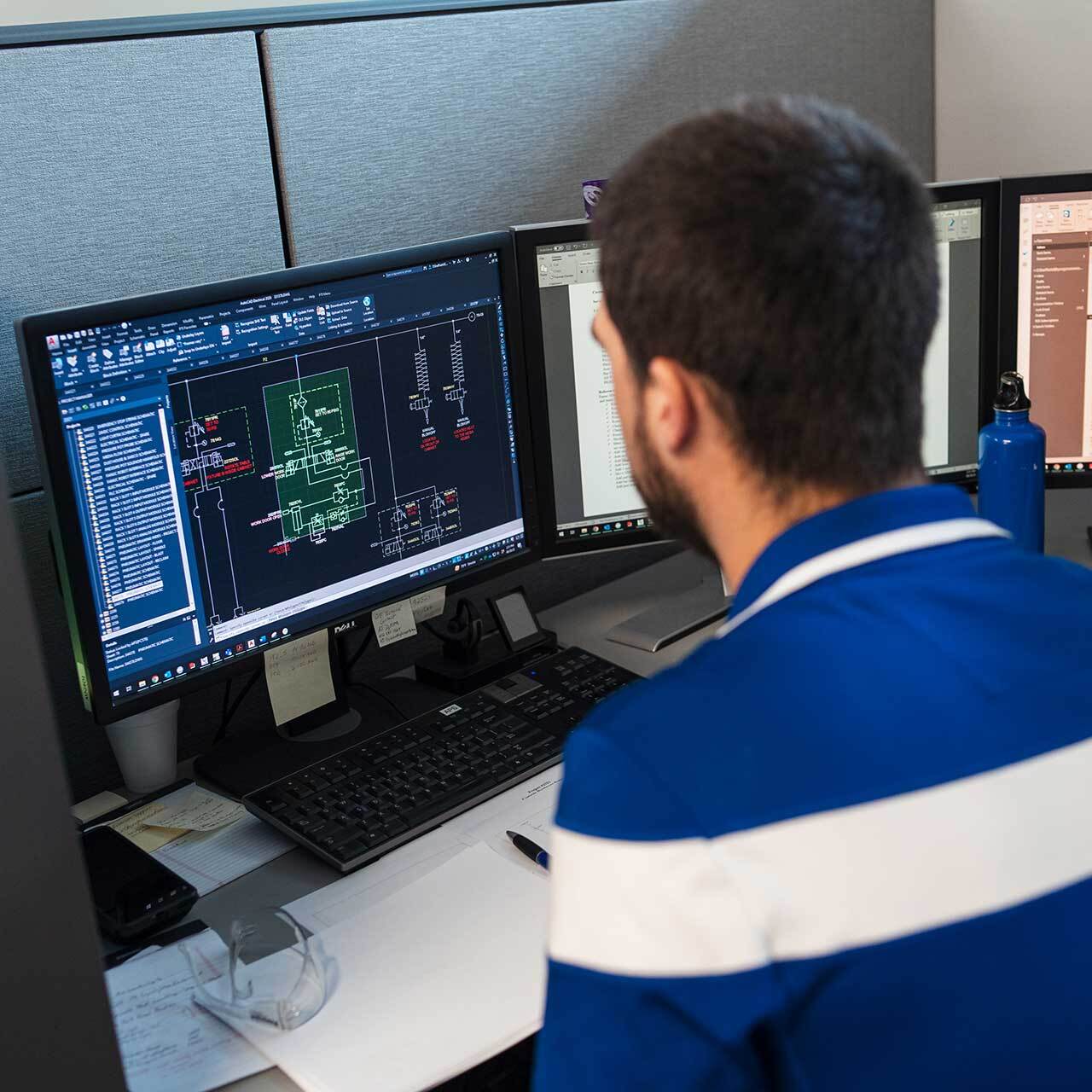

To present a tailored technical proposal, our sales engineers work with the customer and internal engineering departments to consider the process requirements, part diversity, and return on investment. Part features and process requirements are unambiguous in a detailed manufacturing drawing, so that’s where we start. You’ll understand the benefits of our Procise Process® when you receive a technical proposal that exactly fits your project goals.

- Thorough upfront discovery by the experienced sales team

- Comprehensive technical proposals present a well-thought-out project plan

- Dedicated sections of the proposal detail the included and optional hardware and services provided

- Turn-key options include production-ready part programming and detailed operation sheets

Related Machines

PRIMS Pro® Process Reporting and Integrated Monitoring System

Advanced, flexible process control for shot peening, grit blasting, and waterjet cleaning.

Read More

Gantry Robotic Shot Peen System with Sliding Door

Right-sized cabinet for aircraft engine Maintenance, Repair, and Overhaul (MRO).

Read More

Heavy Duty Truck Transmission Gear Peen

Highly productive indexing table with two spindles per station.

Read More

Robotic Wet Ceramic Airfoil Peening System

Light-intensity peening with media concentrations up to 50%.

Read More