Automotive Applications

Home / Industries / Automotive

Reliability and Automation that Optimizes Efficiency

Progressive recognizes the critical need for reliable machinery that maintains continuous part flow to sustain assembly operations. Progressive solutions deliver reliability and automation that enhance production efficiency, reduce cycle times, and curb waste. Comprehensive support services minimize downtime and optimize operational efficiency.

Progressive Automotive Applications

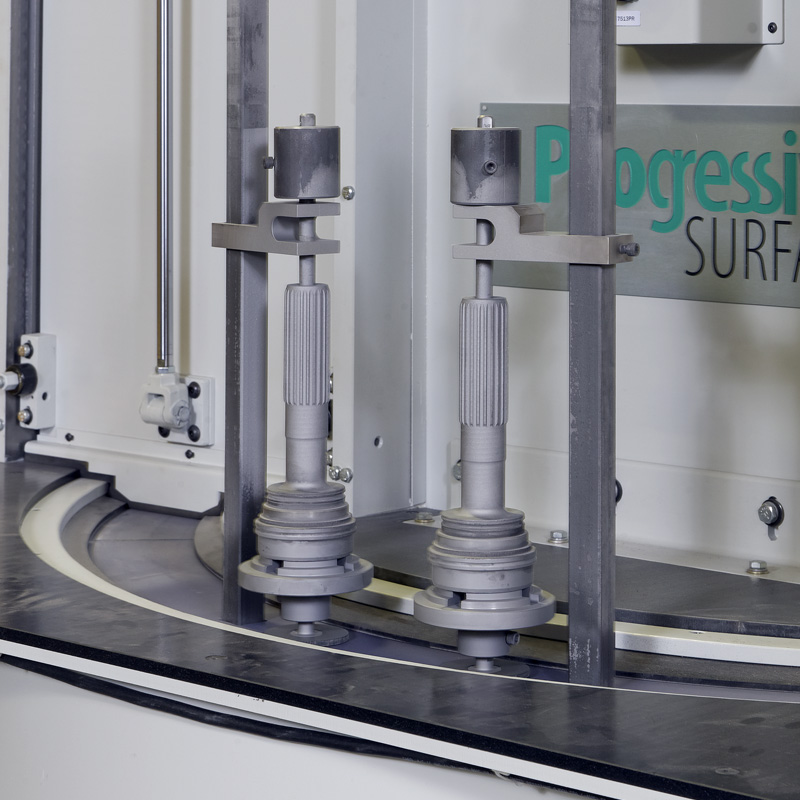

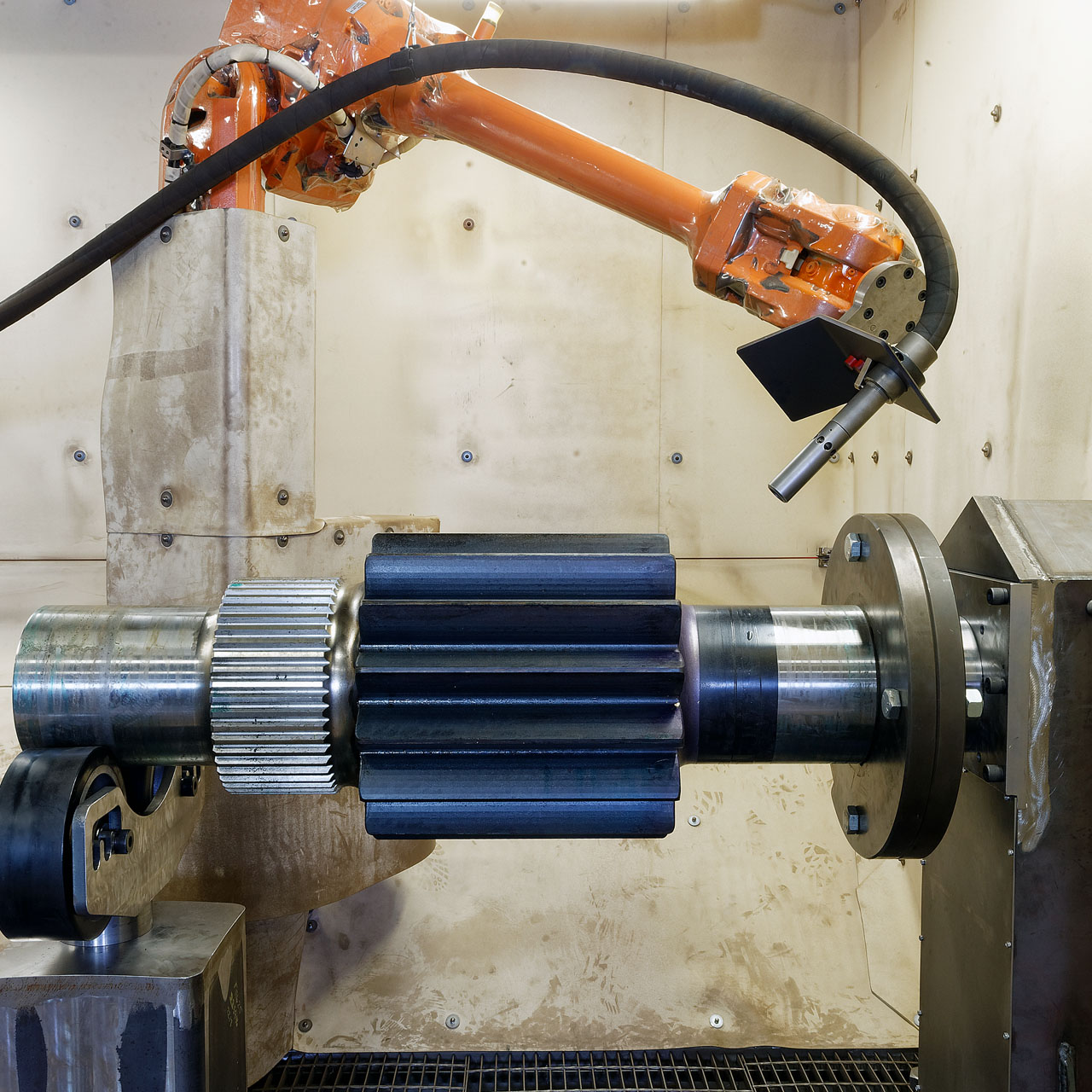

- High volume, high-intensity transmission gear peening

- Precision automated deburring system for cross-drilled holes

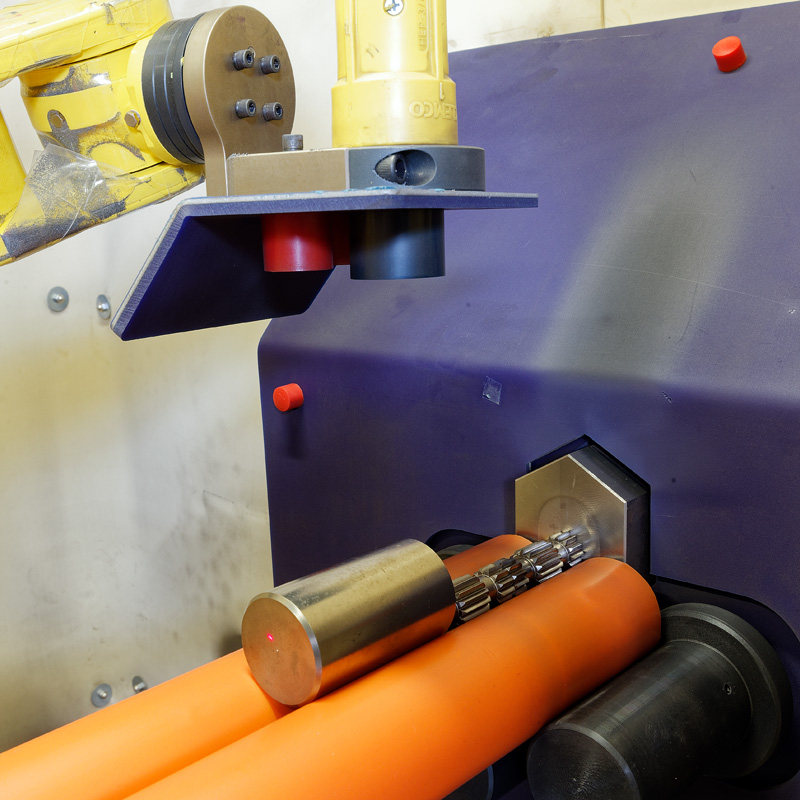

- High volume surface texturing of automotive small components

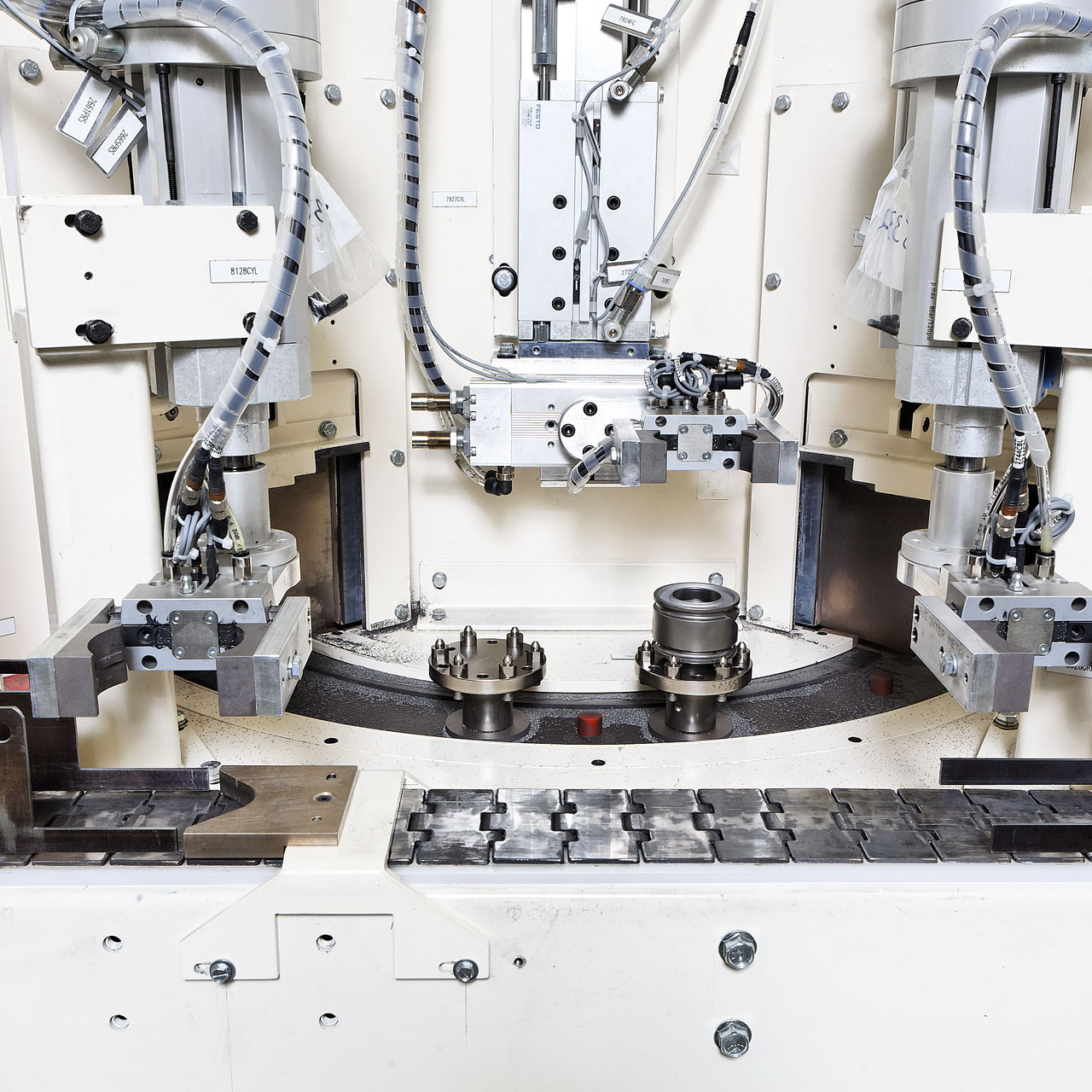

- High production rotary dial table shot blast surface blending on automotive cast components

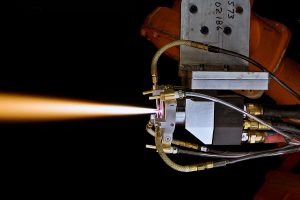

- Thermal sprayed piston rings

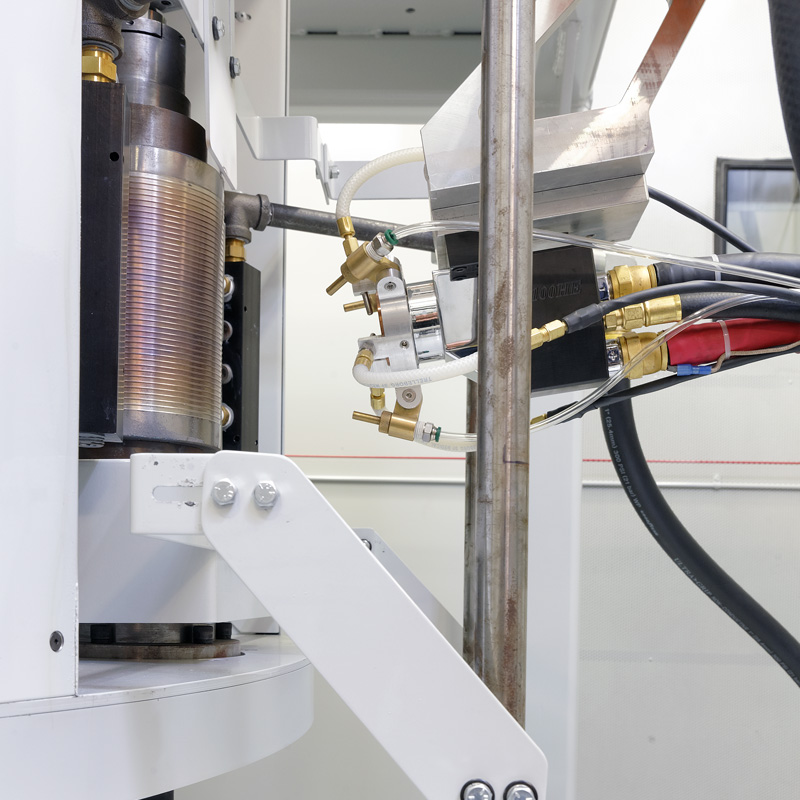

- Shot peening of critical high-pressure fuel injection components

- Shot peening and deburring automotive engine crankshafts

Machines for Automotive

Process Development Capabilities

ABB Arm and Rail Sheet Organizer for Laser Bed Tending

Automated Sheet Handler for Large Hydraulic Press

Automated Sheet Stacker for Laser Bed Tending

CITS Pro® Computer Integrated Thermal Spray Systems

Compact Arm Robot Shot Peen Dual Spindle Table

Gantry Area Sheet and Waste Handler for Laser Bed Tending

Gear Peening for Large Mining Equipment

Heavy Duty Truck Transmission Gear Peen

High Volume Grit and Shot Blast Line

Lean Automated Turbine Blade Root Peen

Multi-Station Tube Shot Blasting with Robotic Handoff

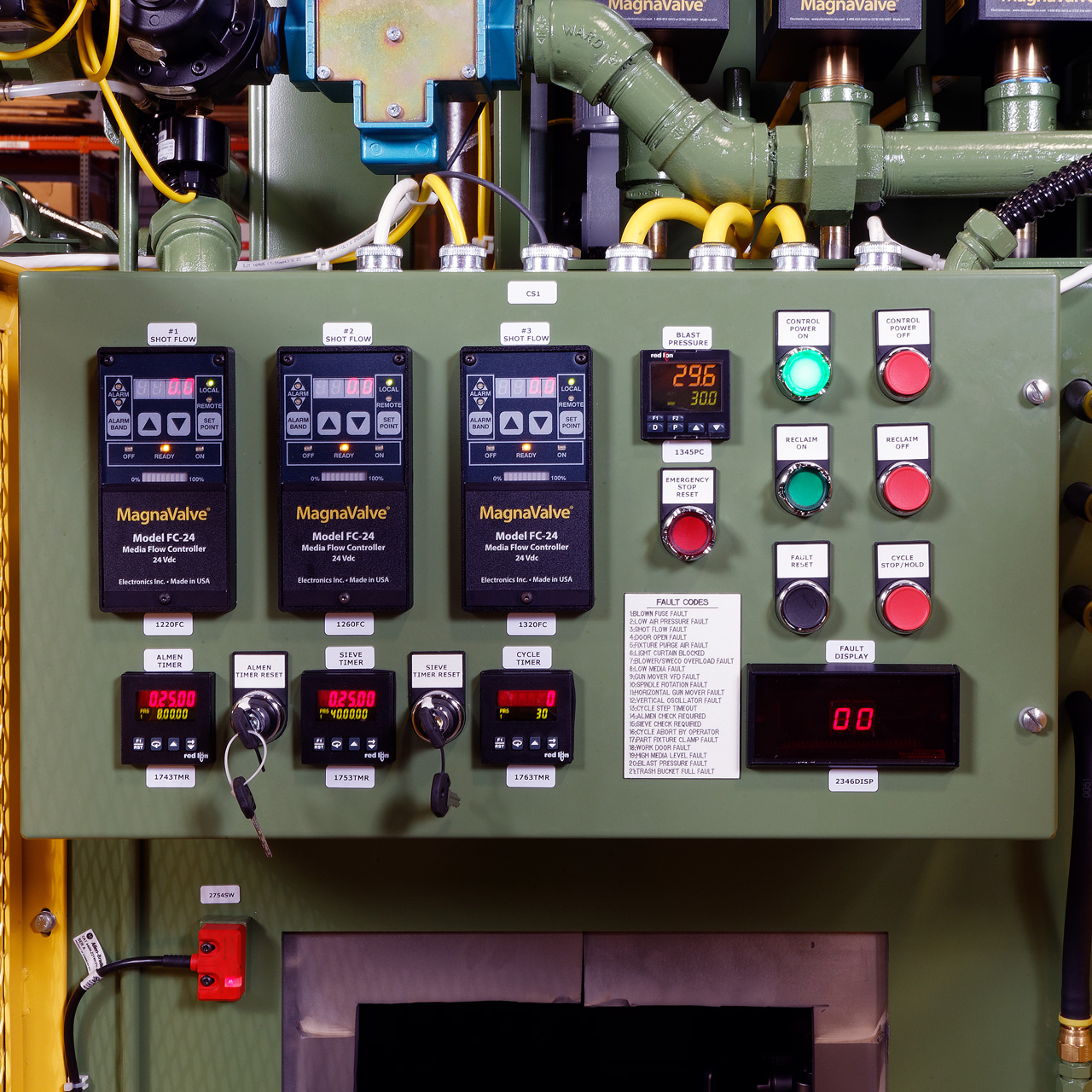

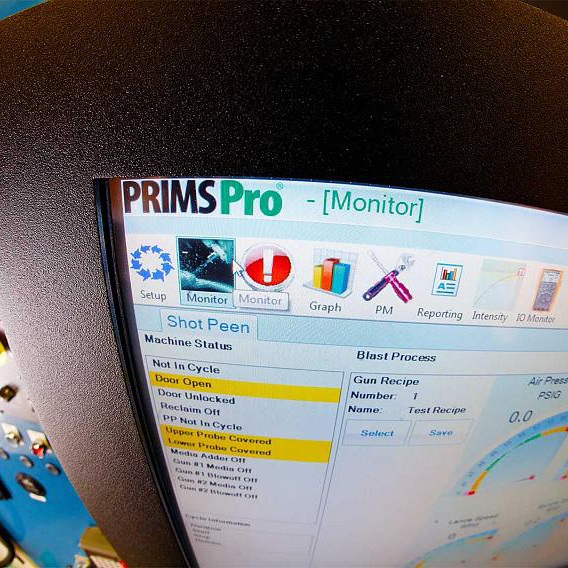

PRIMS Pro® Process Reporting and Integrated Monitoring System

Shot Peening Machines with Multiple Media Types and Sizes

Waterjet Investment Casting Shell Removal

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.