New commercial aircraft designs are providing additional challenges for component manufacturers and processers. With the rising price of fuel, airline operators have been pushing aircraft manufacturers to provide, and guarantee, lower operating and per-seat costs. Total aircraft weight is a major factor when the goal is to increase efficiency and lower cost.

At Progressive Surface, we’ve seen firsthand the traditional aluminum airframe structures morph into larger but lighter components. In some cases, the materials have changed as well to meet strength-to-weight goals. Specifically, we’ve witnessed wing rib structures increase in size to suit the larger wings but machined thinner to minimize weight.

During shot peening, these complex structures can distort and expand lengthwise. The part distortion must be eliminated and the part growth must be controllable and absolutely repeatable. Unfortunately, there isn’t a “one-size-fits-all” solution. Some parts are symmetrical side-to-side along the length and some parts are asymmetrical with one side that is flat without structural features and the opposite side is a complex array of intersecting structural and strengthening features. As is the case of the asymmetrical parts, there is a major imbalance with much more surface area on the structurally complex side of the part than on the flat side.

If this doesn’t cause enough problems, add in the condition of varying part thicknesses commonly found on the latest generation of aerostructure components. How can we effectively shot peen these parts and maintain critical part dimensions?

Shortcomings of Traditional Part Processing

For years, large aerostructures have been shot peened with centrifugal wheel systems that use multiple fixed-wheel positions to achieve part coverage. Some of these systems incorporate up to 24 wheel units to satisfy the part size and geometry. (Read The Shot Peener, “Rising to the Challenge, page 8, Fall 2009.) Due to the fixed positions of the wheels, the blast pattern “hot spots” become very difficult to manage on aluminum structures. Dimensional control is difficult.

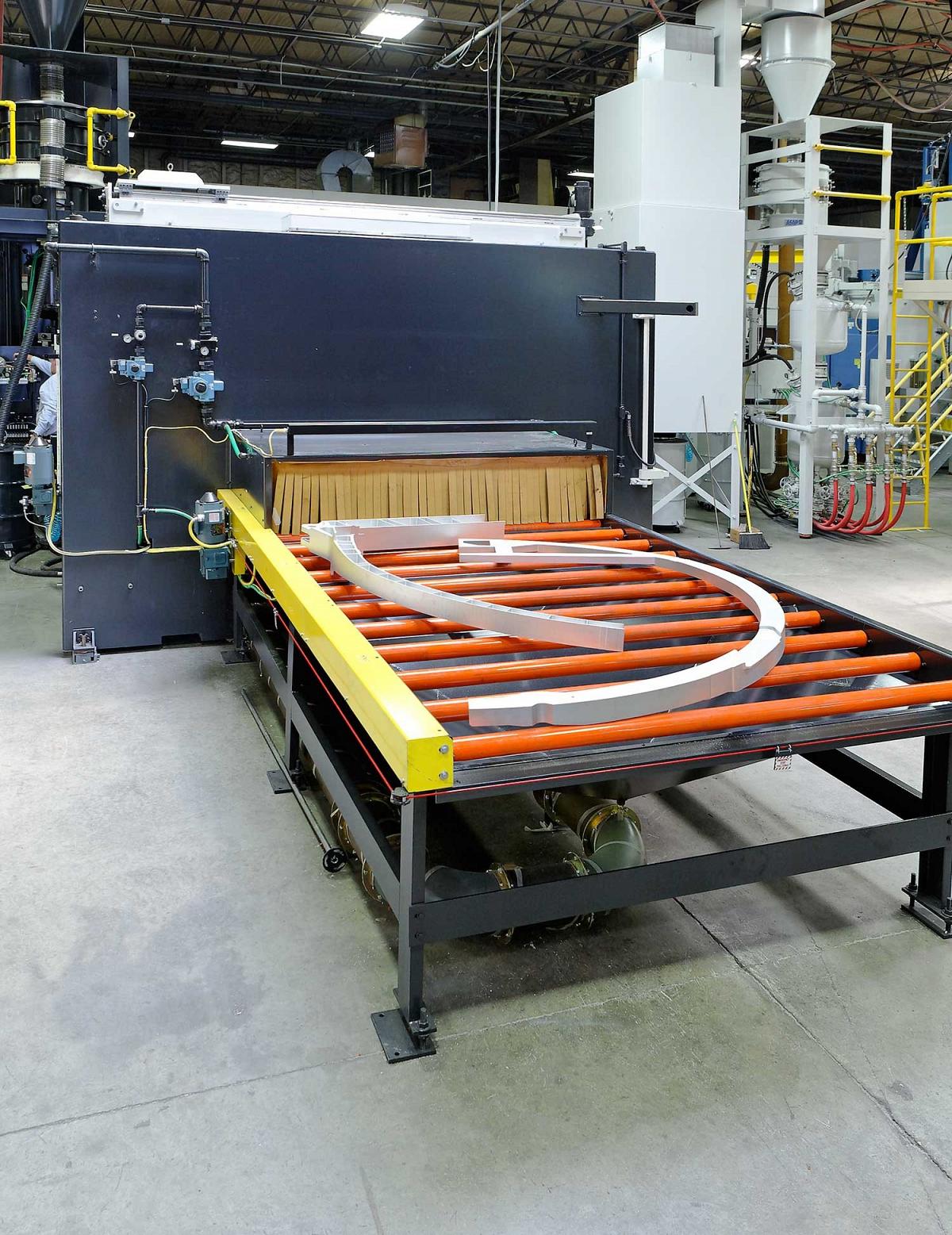

Another approach is to shot peen components oriented on a platen or roll conveyor as they pass through the shot streams of moving nozzles. One side is peened and then the part is turned over and the other side is peened. Some can peen both the upper and lower surfaces in a single pass.

The two-sided method has limitations when trying to process asymmetrical parts, which as discussed, are not equal side to side. Commonly, the flat side faces downward to allow conveyance on rollers. The flat surface gets much higher (sometimes 4:1) part coverage than the complex side during processing. The top and bottom method of shot peening doesn’t work well with complex, symmetrical components either as they aren’t flat and don’t convey well at all unless fixtured.

A Flexible, Modern Solution for Complex Aerostructures

Progressive Surface has designed and commissioned a vertical, two-sided robotic peener for GKN Aerospace of St. Louis. These dual-gantry, CNC-controlled robots can shot peen both sides of aerostructures simultaneously with equal or varying programmed peening coverage. Four peening nozzles are positioned on each of two robots located on either side of the vertical monorail conveyor. The peening nozzles are strategically positioned at compound angles to access all part surfaces. The two robotic manipulators can operate completely independently or coordinated with each other to provide different results. Commissioning has shown the following operation modes:

- Peen both side simultaneous, coordinated and equal. The parts can be peened to 100% or 200% in a single pass or build up to this coverage with multiple, high-speed passes, depending on part growth and distortion.

- Peen the complex side of asymmetrical parts only on the first pass (or multiple passes) then complete the part with all eight nozzles operating in a coordinated controlled mode to complete both sides of the part requirements. This method provides excellent part shape and size control.

Some large ribs have very thin sections between the structures that require masking to prevent shot peening. The new shot peener is CNC controlled and the nozzle clusters will trace the structural features of the part to ensure full coverage. In a follow-up program, it will then peen the complete part and either hit the masking or minimally hit the masking to complete the part, thereby saving time.

Lastly, when complex, asymmetrical parts are processed, the structural features of the complex side of the part can be traced with double the normal media flow. The four nozzles with high media flow are rapidly moved over the features, creating fast part feature coverage. Once the complex areas are peened, all eight nozzles are turned on to the normal media flow and the part is completed in the next peening pass.

Progressive Surface has encouraged GKN aerospace to maximize the system’s efficiency by running mixed and multiple parts numbers per batch or load (filling the part fixture). The parts must all have the same shot peening coverage and intensity requirements as well as being of the same material or alloy.

A CNC-programmed Gantry Robot was chosen for this application due to its robust design and ease of programming. The part geometry of wing ribs is very linear and simple, therefore a six-axis, industrial robot was not needed.

Control, flexibility and repeatability are the core design pillars for this shot peening system.

A Brief Overview of the Machine

- Two overhead Gantry Robots with a total of eight peening nozzles

- Coordinated CNC overhead monorail with large manganese steel “picture frame” fixtures

- Efficient, pneumatic reclaim system with 100% of the reclaimed media classified

- CNC interpolated axis, closed loop media and compressed air control

- PRIMS Pro Operator Interface with process control, monitoring, PM and report generating

- Dual track switching of the monorail allows loading and unloading during the peening process

- Two pneumatic part manipulators to assist the operators when loading and unloading parts

- Power Requirements–130 FLA, Compressed Air–1,300 CFM at 80 psi (37 CM/m at 5.5 bar)

In closing, the quest to reduce aircraft weight is here to stay. Reducing the aircraft total weight is a major factor for increased fuel efficiency and lower operating costs in our competitive world. We’re expecting the use of composites as well as new alloys to reduce weight. The traditional machined and fabricated airframe structures are now machined as large, single monolithic pieces, with cross sections thinned to further reduce weight. Aircraft engine designers are also advancing the strength-to-weight ratios, using new materials and techniques to reduce engine weight and operational costs.

As shot peen processors, we need to keep pushing the envelope and develop methods of peening the new structures in order to meet the weight and cost reduction goals of our industry.

At Progressive Surface, we’ll continue to provide thorough, upfront discovery, process-specific designs and our promise of lifetime support.