CITS Pro®

Home / CITS Pro®

CITS Pro® Provides Unmatched Thermal Spray Process Control

Progressive Surface’s CITS Pro®—Computer Integrated Thermal Spray—system provides unmatched multi-process closed loop control, versatility, security, and data logging for multiple thermal spray processes.

Combining a powerful PLC with a user-friendly, touchscreen PC, the CITS Pro® controller is designed with both operators and process engineers in mind.

The Industry’s Most Advanced Process Controller

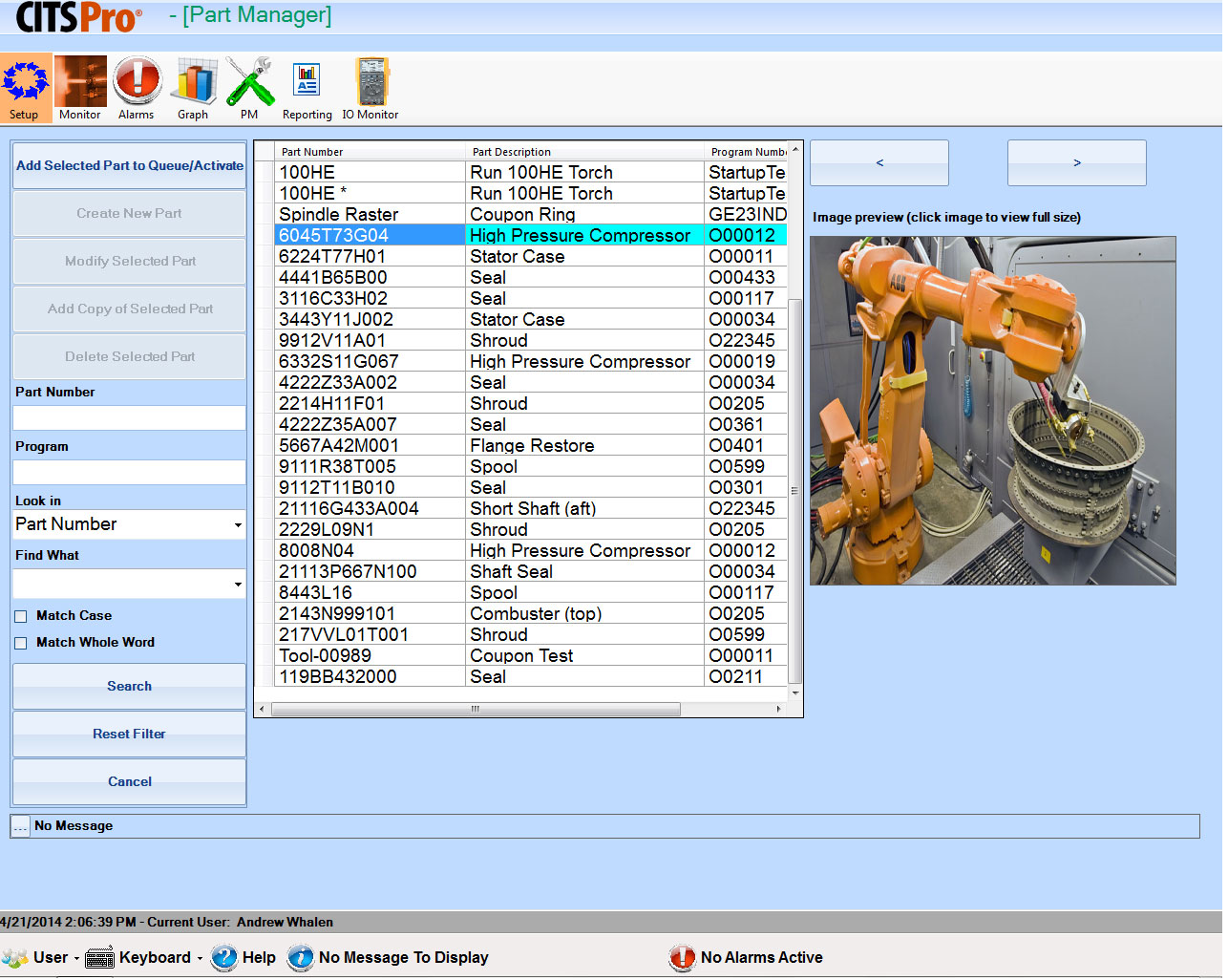

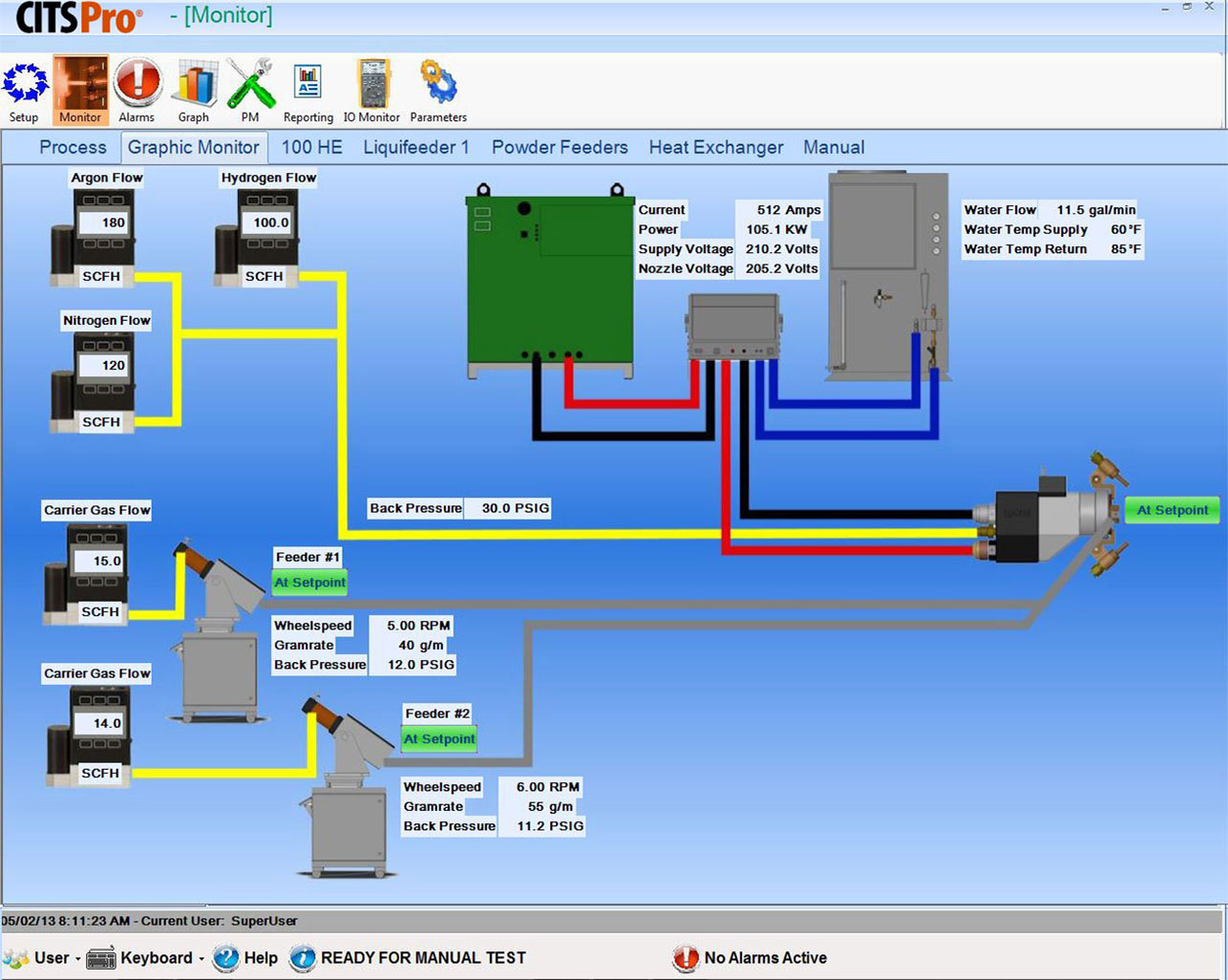

Each CITS Pro® system is customized for its specific application and can be configured to control individual or multiple high energy plasma, conventional plasma, HVOF, arc, and flame spray processes.

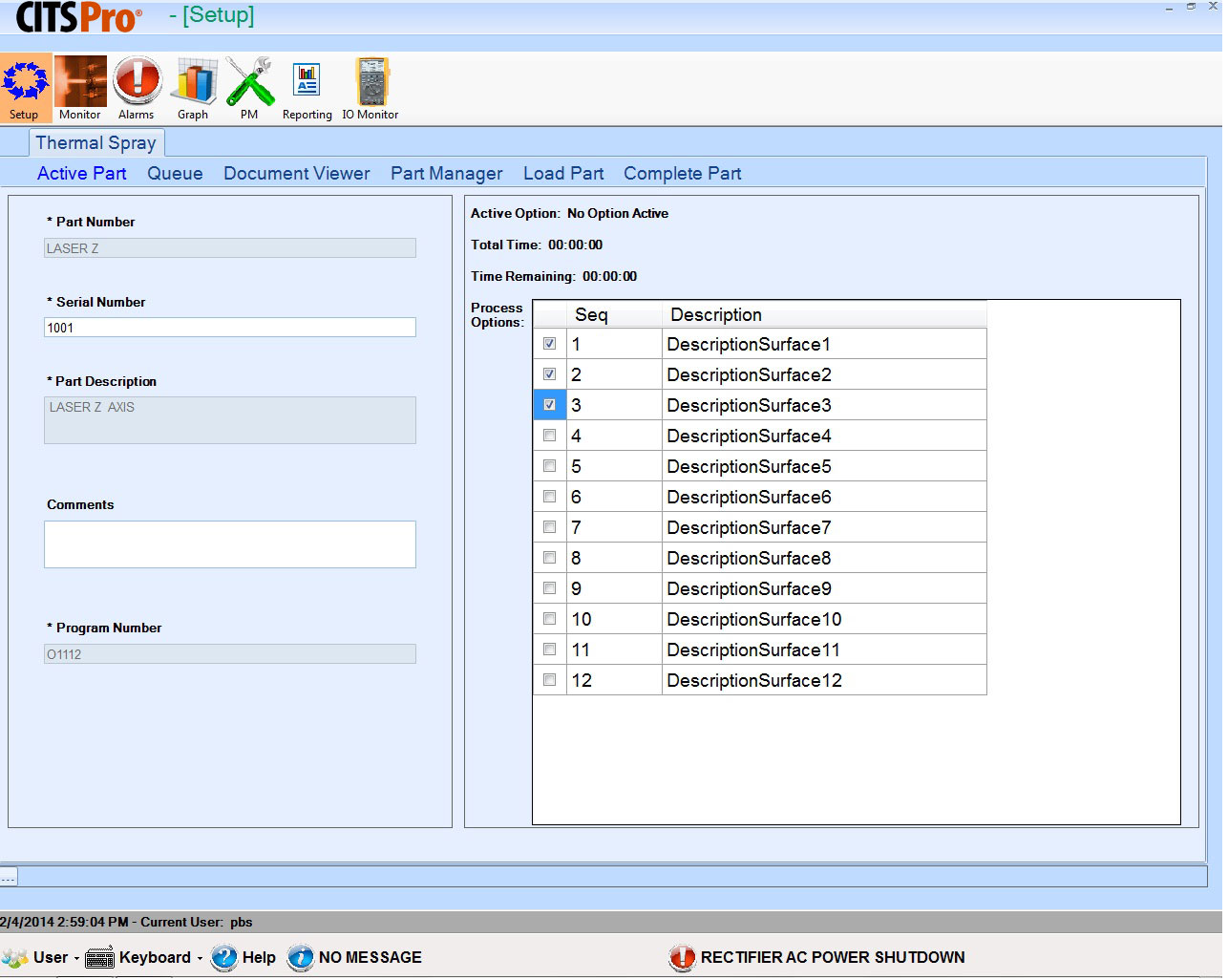

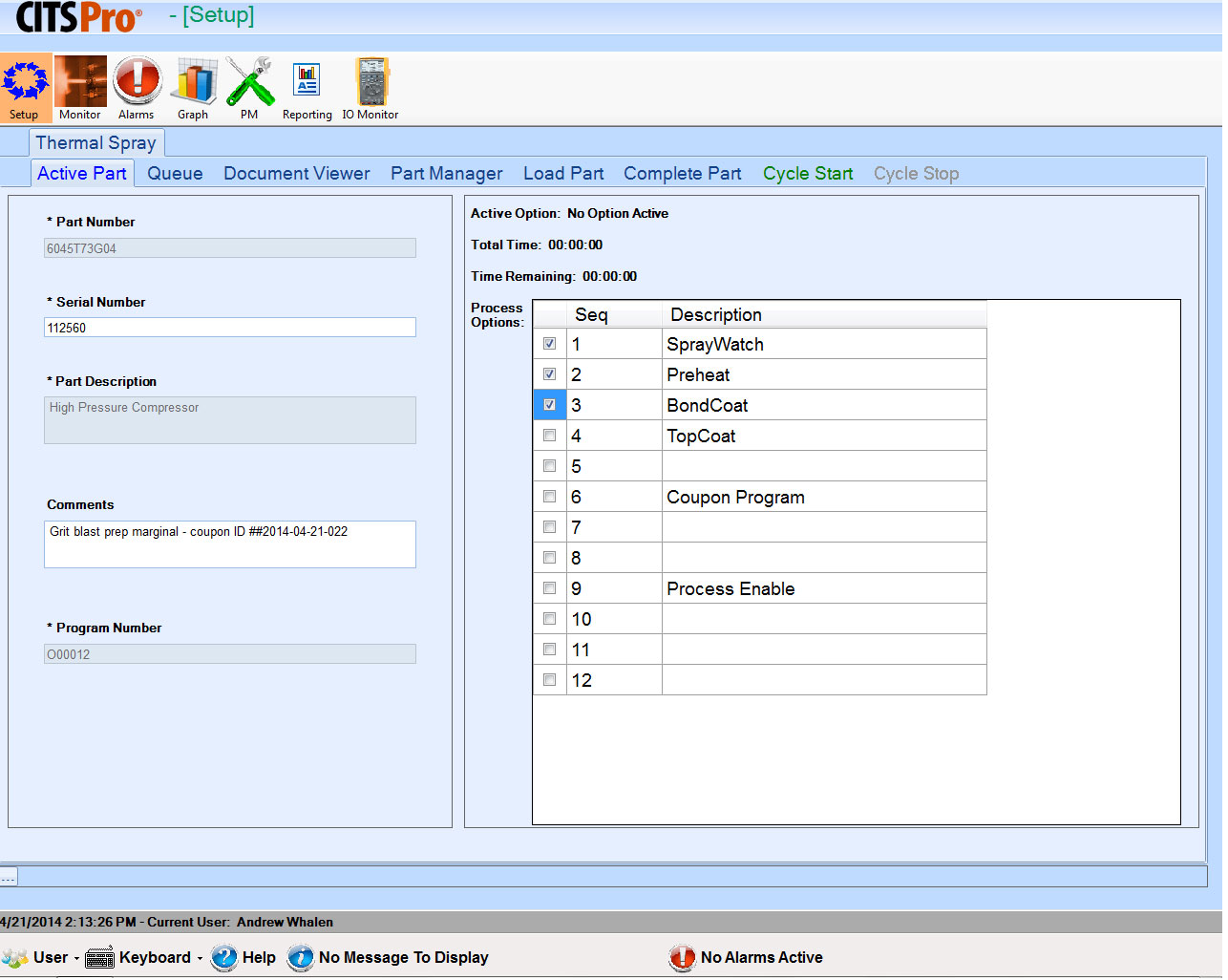

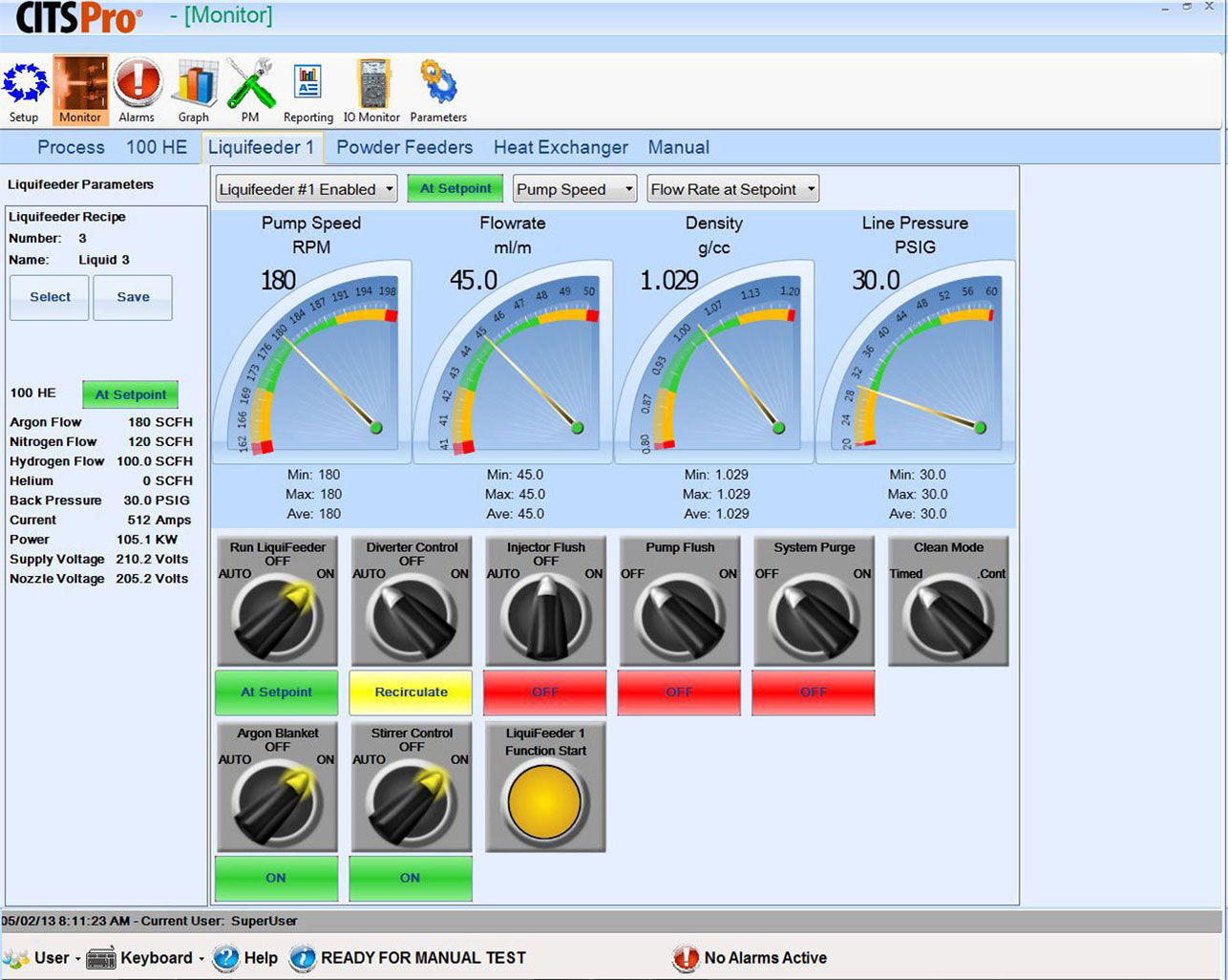

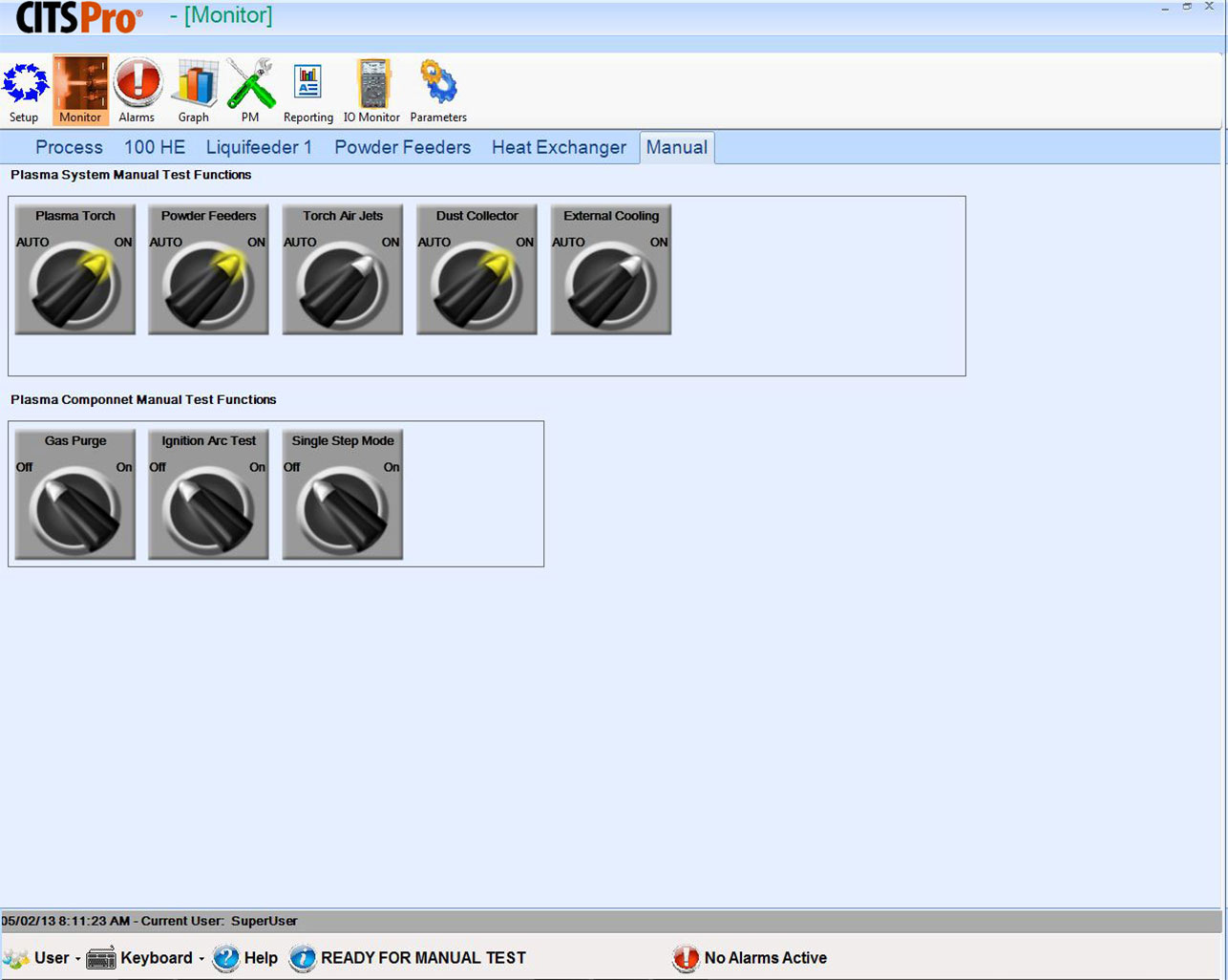

CITS Pro® enables manual, automatic, local and remote monitoring and operation using stored parameters. Extensive context-sensitive help and intuitive Windows-based controls make the CITS Pro® system very easy to use.

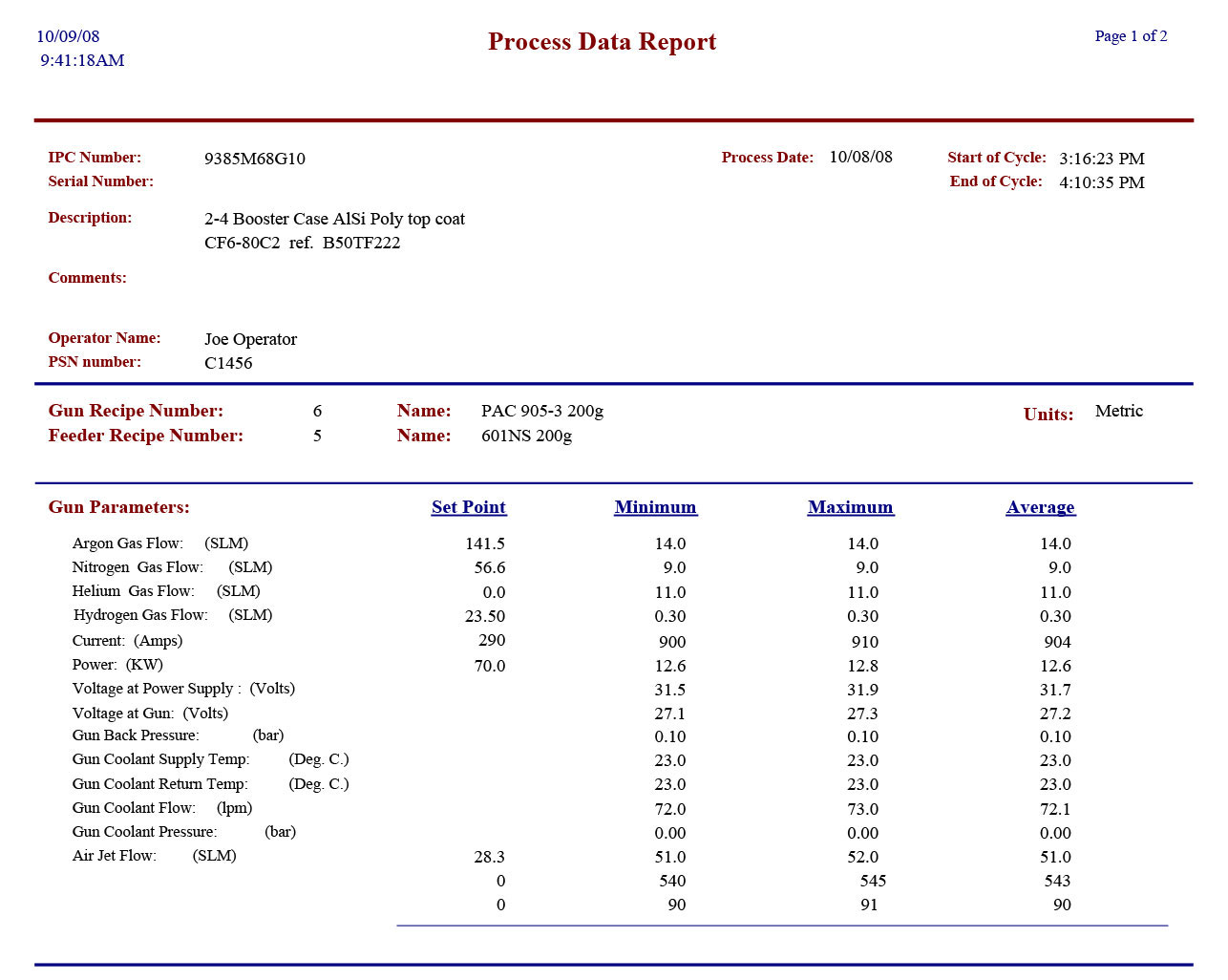

Configurable data loggers record specified variables every second the machine is “in-cycle.” Trend graphs provide the process engineer with the tools to perform design of experiments or SPC evaluation.

With selection of proper process hardware, CITS Pro® controller software can operate up to six powder feeders with closed loop feedrate control.

Additional CITS Pro® features & benefits

- Closed-loop control of all thermal spray process parameters with limits displayed on same screen

- Powerful recipe management displays process status, enables adjustment of process parameters, and stores and displays recipes

- Productivity data and process costs documented and analyzed

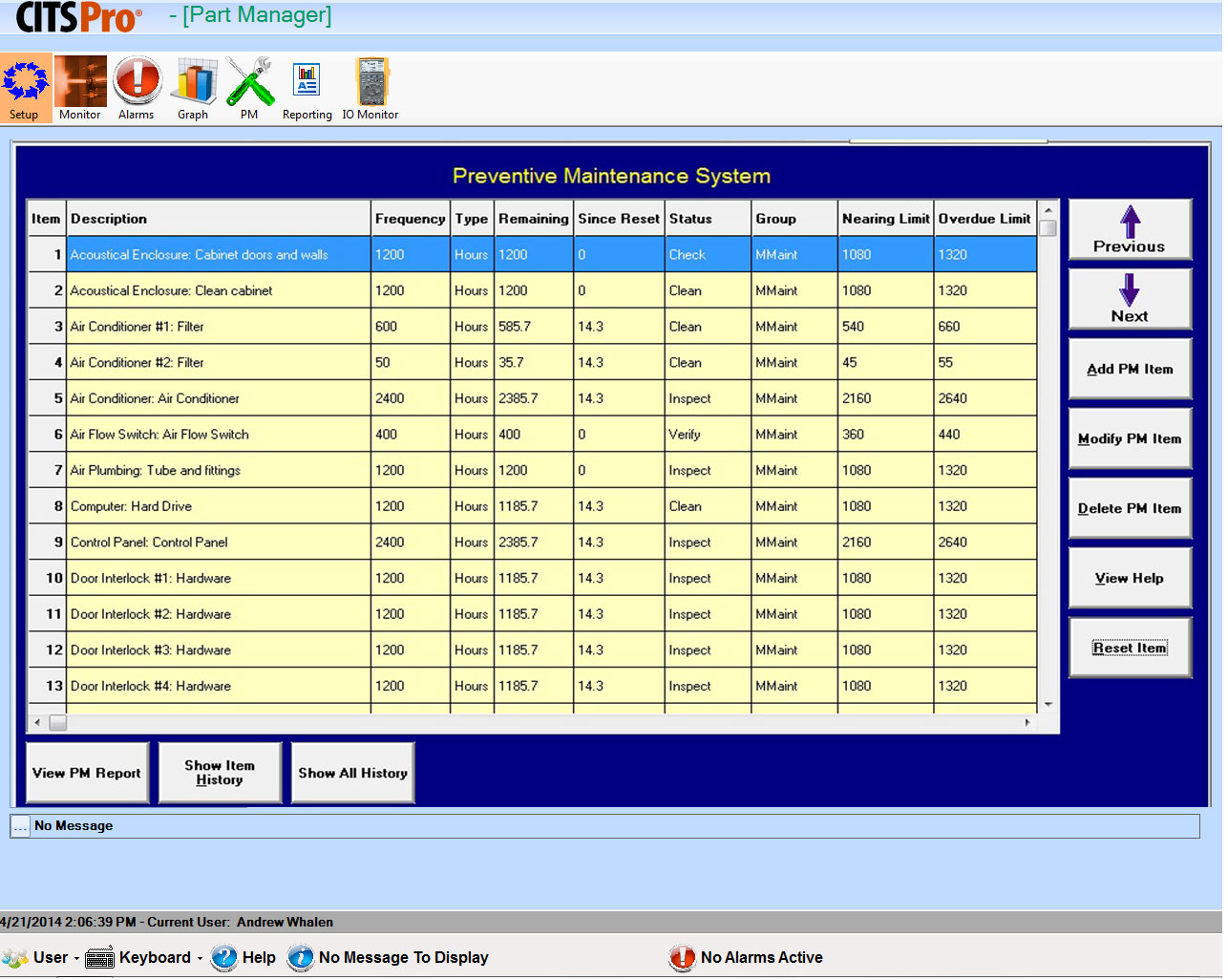

- Preventive maintenance enables decreased downtime and increased productivity

- Powder feeder module can operate two feeders at once

- Team Viewer software allows the user to connect with Progressive Surface engineers for remote access and diagnosis of any problem