Custom Automation

Our unique combination of system engineering expertise, leading edge process development, and lifetime support, allow us to provide customers with the right solution to their processing needs.

Custom Automation Machines

Process Development Capabilities

Leverage our nearly 60 years of process and equipment design knowledge.

Read More

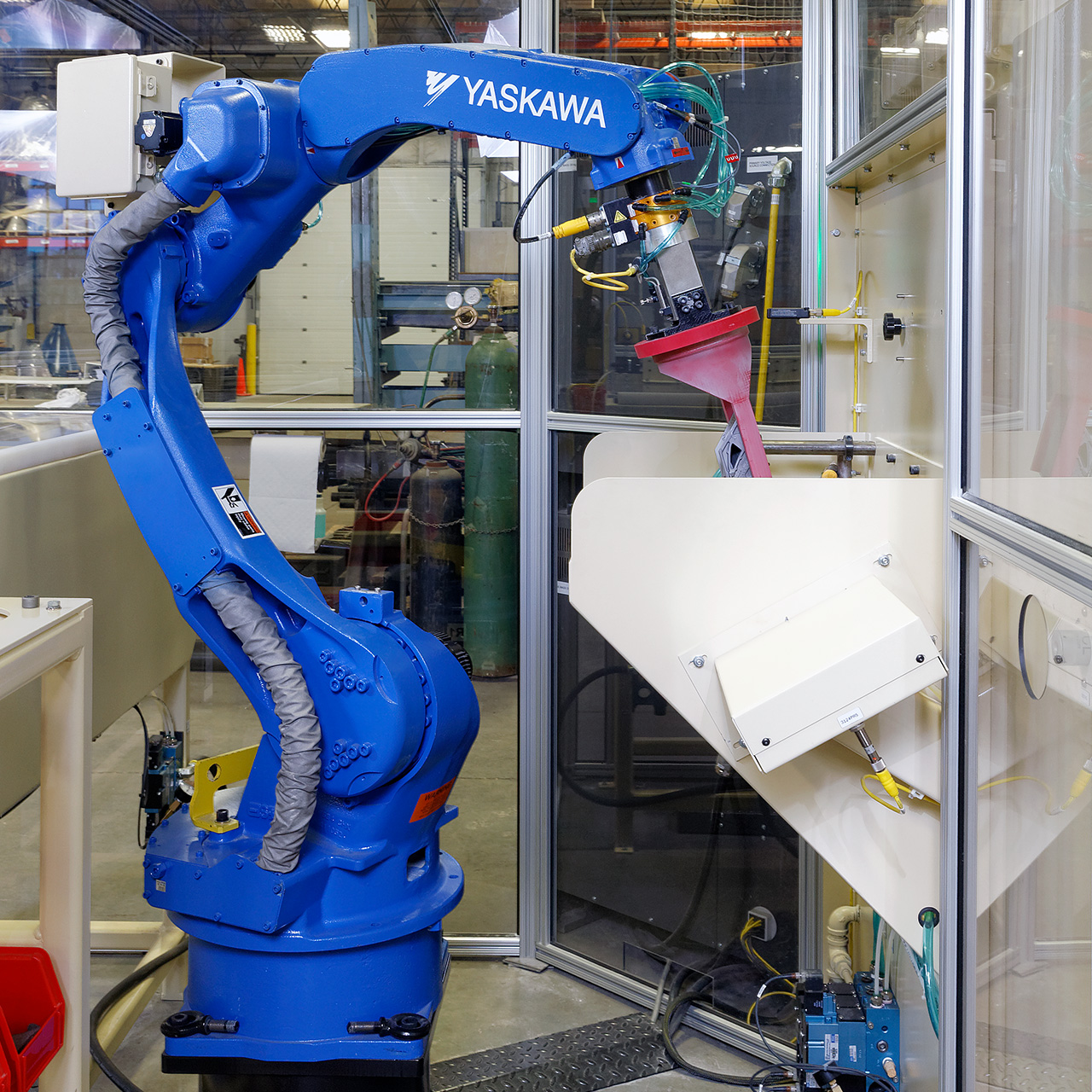

Double Robotic System to Etch Aircraft Engine Components

One robot loads and rotates the part, while a second manipulates the nozzle.

Read More

High-Capacity Manipulator for Arc Spray Application

Integration of robot, spindle/positioner, and thermal spray equipment for salvage and repair.

Read More

Multi-Station Tube Shot Blasting with Robotic Handoff

ID blasting with horizontal lance and OD blasting with nozzles on automotive forgings.

Read More

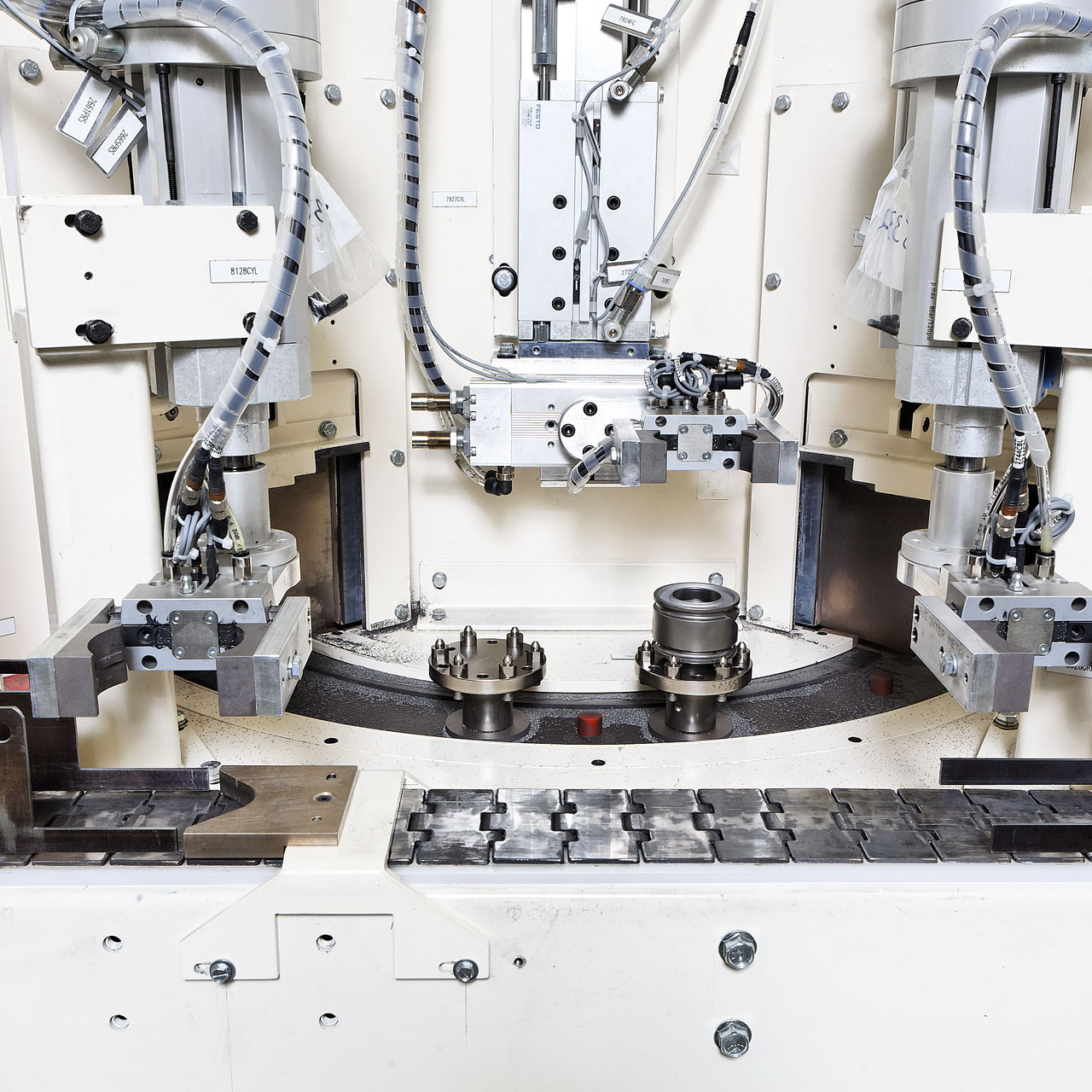

High Volume Grit and Shot Blast Line

Side-by-side small rotary index machines perform two blast cleaning operations.

Read More

Automated Sheet Stacker for Laser Bed Tending

Up to eight drawers for sheet material storage and loading onto laser bed.

Read More

Gantry Area Sheet and Waste Handler for Laser Bed Tending

CNC-controlled gantries for loading full sheets and retrieving and stacking cut parts.

Read More

ABB Arm and Rail Sheet Organizer for Laser Bed Tending

Robot on rail selects material from 24 different drawers.

Read More

Walking Beam System for Abrasive Blast Long Tube Inside Diameters

High production surface etching uses the tube as the blast chamber.

Read More

Automated Sheet Handler for Large Hydraulic Press

Integrated gantry, conveyors, and feed system, all controlled by CNC.

Read More

Automated Cell for Blade Tip Coating

Large turbine blades are robotically handled through grit blast, plasma spray, and a finishing operation.

Read More