Custom Automation

Home / Custom Automation / Double Robotic System to Etch Aircraft Engine Components

Double Robotic System to Etch Aircraft Engine Components

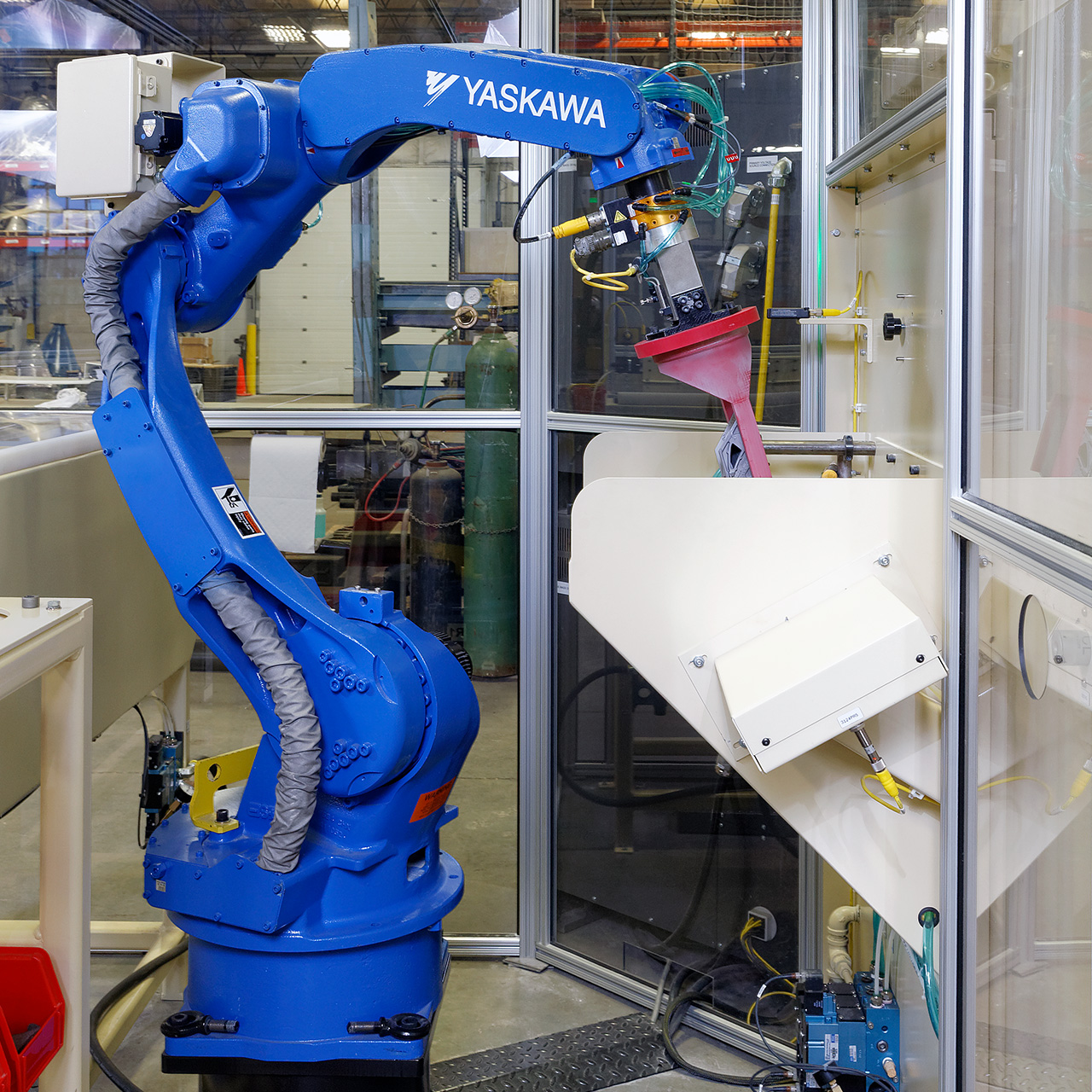

One robot loads and rotates the part, while a second manipulates the nozzle

The double drawers allow the operator to load a batch of parts while the loading robot is actively manipulating a part in the safe operating zone. Once loaded, the operator closes the drawer, manually slides the safety door closed, and arms the system for the next cycle. When the robot completes a drawer of components, the system automatically shifts the drawer’s protection screen to allow automatic access to the second drawer.

- Manual and automatic safety barriers enable continuous blasting

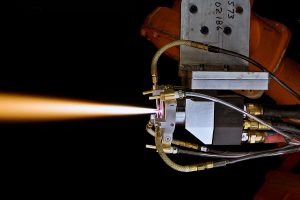

- Robotic nozzle manipulation offers precise and repeatable control of material removal

- Part grippers designed for full coverage in a single blast cycle

- Sensors confirm that each part has been properly gripped

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Automated Cell for Blade Tip Coating

Process Development Capabilities