Custom Automation

Home / Custom Automation / Gantry Area Sheet and Waste Handler for Laser Bed Tending

Gantry Area Sheet and Waste Handler for Laser Bed Tending

CNC-controlled gantries for loading full sheets and retrieving and stacking cut parts

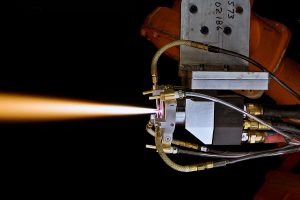

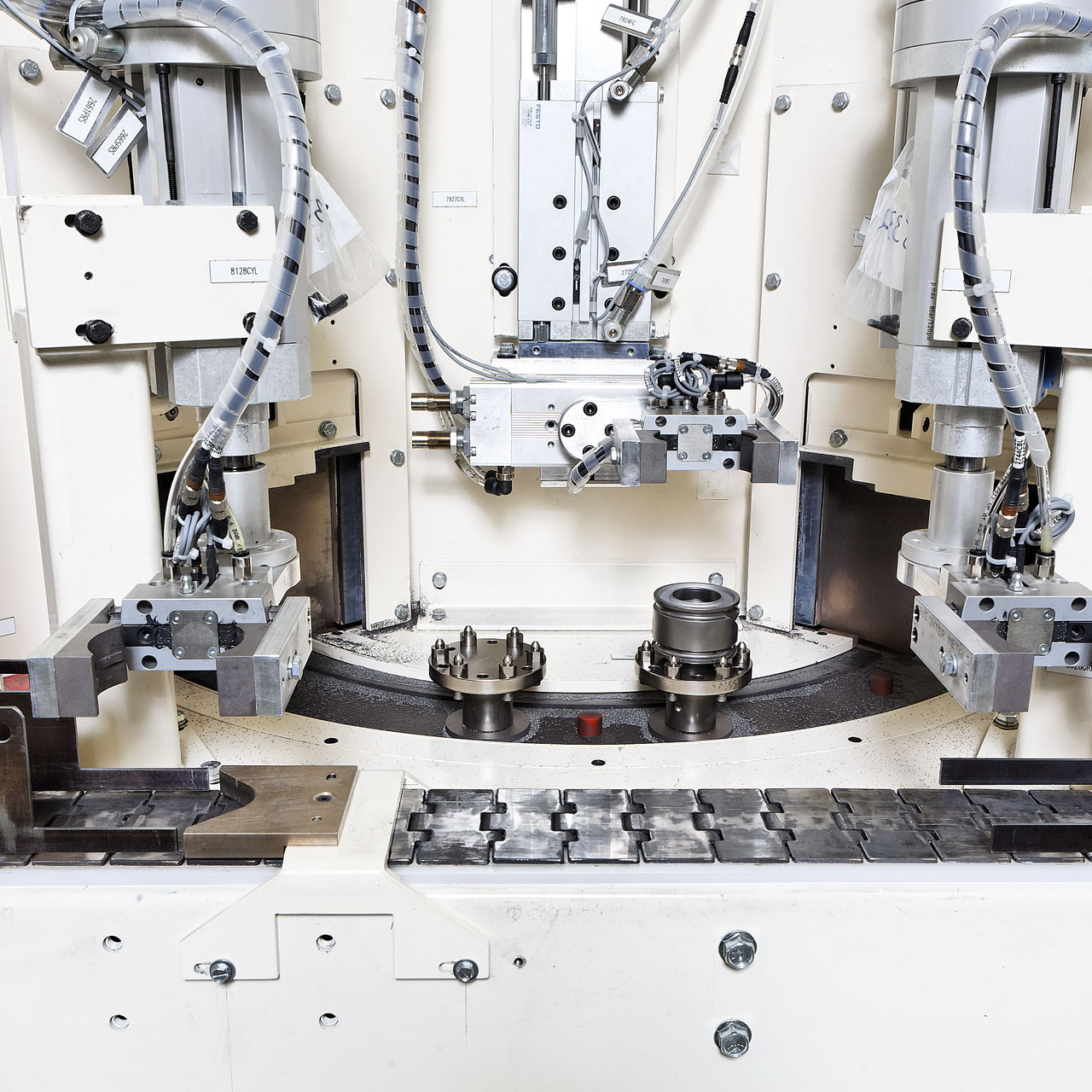

The integration of an advanced material handling system significantly improves the productivity of this advanced laser processing system. Large 6′ x 20′ steel plates are loaded from a mobile incoming material cart onto the bed of the Cincinnati Laser cutting system. Once laser processed, a second four axis part-handling Gantry unloads the finished machined parts into dunnage. A final operation using a special scrap fork is performed to remove fallout and skeletons from the laser bed peening process. This machine design overcomes the unique challenges presented by the environment for creating and maintaining an accurate and repeatable system, especially when robotics and an automatic tool exchange system are incorporated.

- Integration with a start-of-the-art CL707 Cincinnati Laser Cutting system

- Progressive gantry system(s) for sheet handling

- Tool changer for two different suction cup heads

- Automatic scrap removal

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Multi-Station Tube Shot Blasting with Robotic Handoff

High Volume Grit and Shot Blast Line

Automated Sheet Stacker for Laser Bed Tending