Custom Automation

Home / Custom Automation / Walking Beam System for Abrasive Blast Long Tube Inside Diameters

Walking Beam System for Abrasive Blast Long Tube Inside Diameters

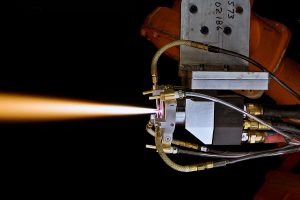

High production surface etching uses the tube as the blast chamber

Most blasting operations require that the entire component be enclosed by a process cabinet in order to contain and reclaim the process media. This system blasts the 240 mesh silicon carbide media through a sealed nozzle at one end of the tube and captures the exiting media from the opposite end with a special reclaim hood. Tubes “walk” between stations in sets of two. To blast from the opposite end of the tube, manipulators move the tubes horizontally after the first blast cycle since the tube lengths vary and the blast stations are stationary.

- Tubes vary in diameter (3/8”-1”) and up to 16’ long

- Large tip-up part loader conveniently loads batches of parts into the load station

- Two independent blast stations, each blasting from the opposite tube end

- Sensors throughout the machine confirm that tubes are “walking” through each station

- Unique blast and reclaim system utilizing the component as the blast enclosure

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Multi-Station Tube Shot Blasting with Robotic Handoff

Automated Sheet Stacker for Laser Bed Tending

Gantry Area Sheet and Waste Handler for Laser Bed Tending