Grit Blasting

Our unique combination of system engineering expertise, leading edge process development, and lifetime support, allow us to provide customers with the right solution to their processing needs.

Grit Blasting Machines

Process Development Capabilities

Leverage our nearly 60 years of process and equipment design knowledge.

Read More

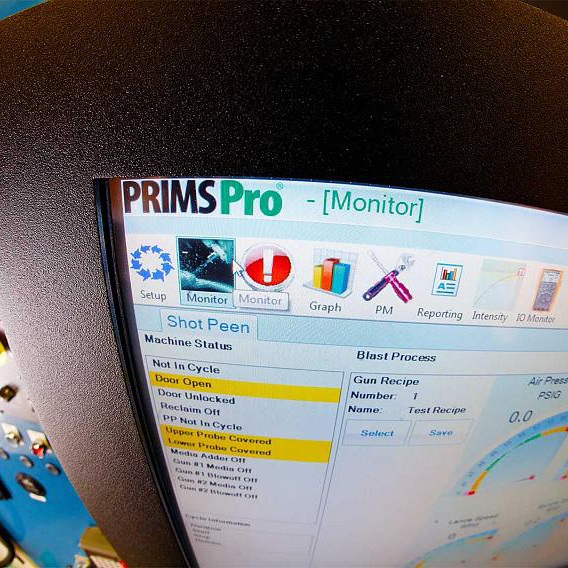

PRIMS Pro® Process Reporting and Integrated Monitoring System

Advanced, flexible process control for shot peening, grit blasting, and waterjet cleaning.

Read More

Small Robotic Grit Blast with Manual Station

Easily switch from robotic to manual nozzle manipulation.

Read More

Fine Mesh Robotic Grit Blast with Drying Station

Reduced part handling by integrating part drying at the load station.

Read More

Large Robotic Grit Blast with Manual Station

Designed to overcome the challenges of very fine mesh media.

Read More

Robotic Turbine Blade Grit Blast with Conveyor

Upstream processes feed the conveyor system with part pallets

Read More

Large Composite Case Robotic Wet Blast

Targeted surface etching in preparation for bonding.

Read More

Dual Spindle Pressure Grit Blast Turbine Blades

Multi-nozzle system is highly productive while also being compact.

Read More

Grit Blast Turbine Nozzles with ABB Robotic Loading

The software and tooling work together to process aero engine parts efficiently.

Read More

Pass Through Mold Cleaning using Plastic Media Blasting

Complex parts are blasted top and bottom; return conveyor brings parts back to front of machine.

Read More

Continuous Rotary Grit Blast

Suitable for general cleaning or surface preparation operations.

Read More