Automatic Robotic Aircraft Engine Nozzle Segment and Blade Grit Blast

Home / Grit Blasting Videos / Automatic Robotic Aircraft Engine Nozzle Segment and Blade Grit Blast

This system is designed to process a tray of parts automatically, utilizing a drawer style part load and two Yaskawa Motoman robots. The tray capacity depends on the size of the individual components. The operator manually loads a tray, closes the safety panel, and arms the zone for automatic processing. He can then walk away from the cell. One robot picks a part from the tray and loads it into the abrasive blast cabinet where the surfaces are targeted for fine mesh grit blasting by a second arm robot. The load robot is able to orient the blade within the cabinet for better targeting by the blast nozzle manipulator. The part is blown down, as is the gripper, to virtually eliminate grit carry-out. The delicate areas of the gripper actuator are also maintained outside the blast environment for reliable operation. Nine different part grippers can be loaded into the cell at one time to handle a large variety of daily production without interruption.

Related Machines

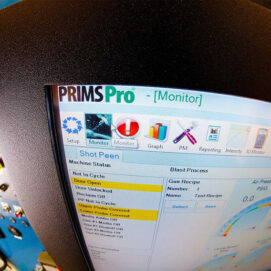

PRIMS Pro® Process Reporting and Integrated Monitoring System

Large Robotic Grit Blast with Manual Station

Robotic Turbine Blade Grit Blast with Conveyor