Robotic Grit Blast Machine for Carbon Composite Structures

Home / Grit Blasting Videos / Robotic Grit Blast Machine for Carbon Composite Structures

This articulated arm robotic machine is configured for processing carbon composite automotive body panel structures. Controlled abrasive blasting of the surface is required to improve adhesion for paint and bonding processes. A dual shuttle system is included to quickly exchange universal load frames to keep parts in front of the robot for high volume production.

The system has a large work envelope with capacity for components up to 60 inches high by 68 inches wide and 10 inches thick. The dual shuttle exchange keeps the Fanuc M710i arm robot with dual blast nozzles busy. The blast delivery system is a dual stage pressure pot for continuous aluminum oxide feeding. Media is reclaimed using a fully pneumatic system that classifies 100% of the returned media for reuse. An Allen Bradley laser scanner provides a barrier to protect an operator in the load area from motion of the part loader.

Related Machines

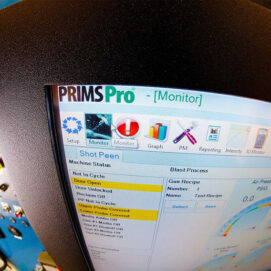

PRIMS Pro® Process Reporting and Integrated Monitoring System

Small Robotic Grit Blast with Manual Station

Fine Mesh Robotic Grit Blast with Drying Station