Grit Blasting

Home / Grit Blasting / Fine Mesh Robotic Grit Blast with Drying Station

Fine Mesh Robotic Grit Blast with Drying Station

Reduced part handling by integrating part drying at the load station

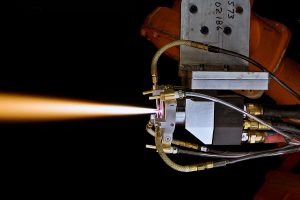

This specialized robotic fine-grit blast machine is designed to dry turbine engine components after washing and lightly etch them before final inspection. To reduce handling time, parts are transferred directly from cleaning tanks to the machine, loaded in a drying chamber, and dried before loading into the blast chamber. The system has two spindles to exchange a new part for a completed part quickly.

- Machine designed to operate with fine media (500 mesh aluminum-oxide)

- Drying chamber

- Articulated arm robot nozzle manipulation

- Continuous-duty pressure pot features media flow monitors

- Closed loop air pressure control

- Media flow monitors

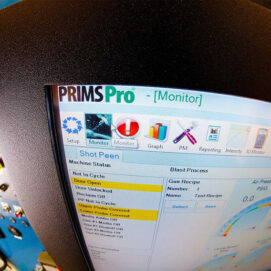

- PRIMS Pro® software

- Integral hoist to load parts (optional)

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

PRIMS Pro® Process Reporting and Integrated Monitoring System

Small Robotic Grit Blast with Manual Station

Large Robotic Grit Blast with Manual Station