Grit Blasting

Home / Grit Blasting / Large Composite Case Robotic Wet Blast

Large Composite Case Robotic Wet Blast

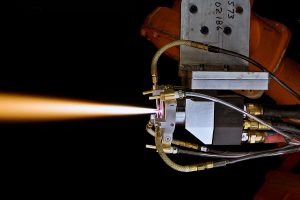

Targeted surface etching in preparation for bonding

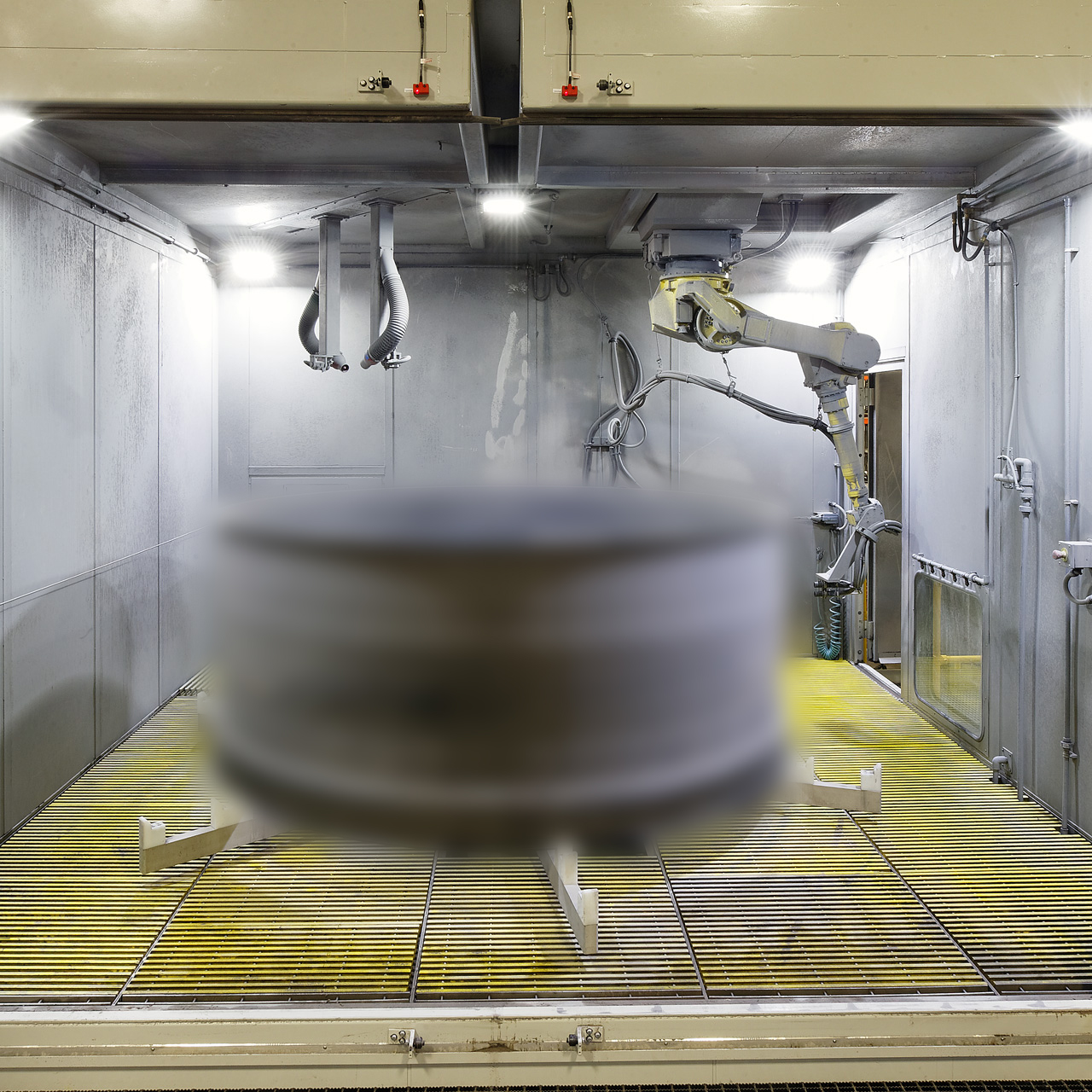

While the cabinet is large, the slurry reservoir is small enough to maintain concentration levels and easily agitate it at startup. Parts are rinsed automatically after the process cycle using deionized water. The engineered water management system maintains the water and media ratio. A water break test confirms that the 180 mesh aluminum oxide and water combination has properly roughened the surface.

- Spindle and robot manipulate parts up to 144 inches in diameter and 60 inches tall

- Inverted Fanuc M710i arm robot manipulates two slurry nozzles

- Heated air handling units dry parts after rinse

- Automatic wash-down system cleans walls and floor

- Powered roof slot provides overhead crane access (optional)

- Turnkey installation (optional)

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

PRIMS Pro® Process Reporting and Integrated Monitoring System

Small Robotic Grit Blast with Manual Station

Fine Mesh Robotic Grit Blast with Drying Station