Grit Blasting

Home / Grit Blasting / Robotic Turbine Blade Grit Blast with Conveyor

Robotic Turbine Blade Grit Blast with Conveyor

Upstream processes feed the conveyor system with part pallets

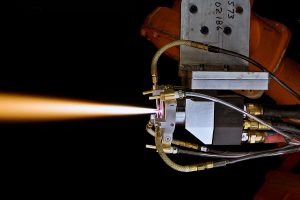

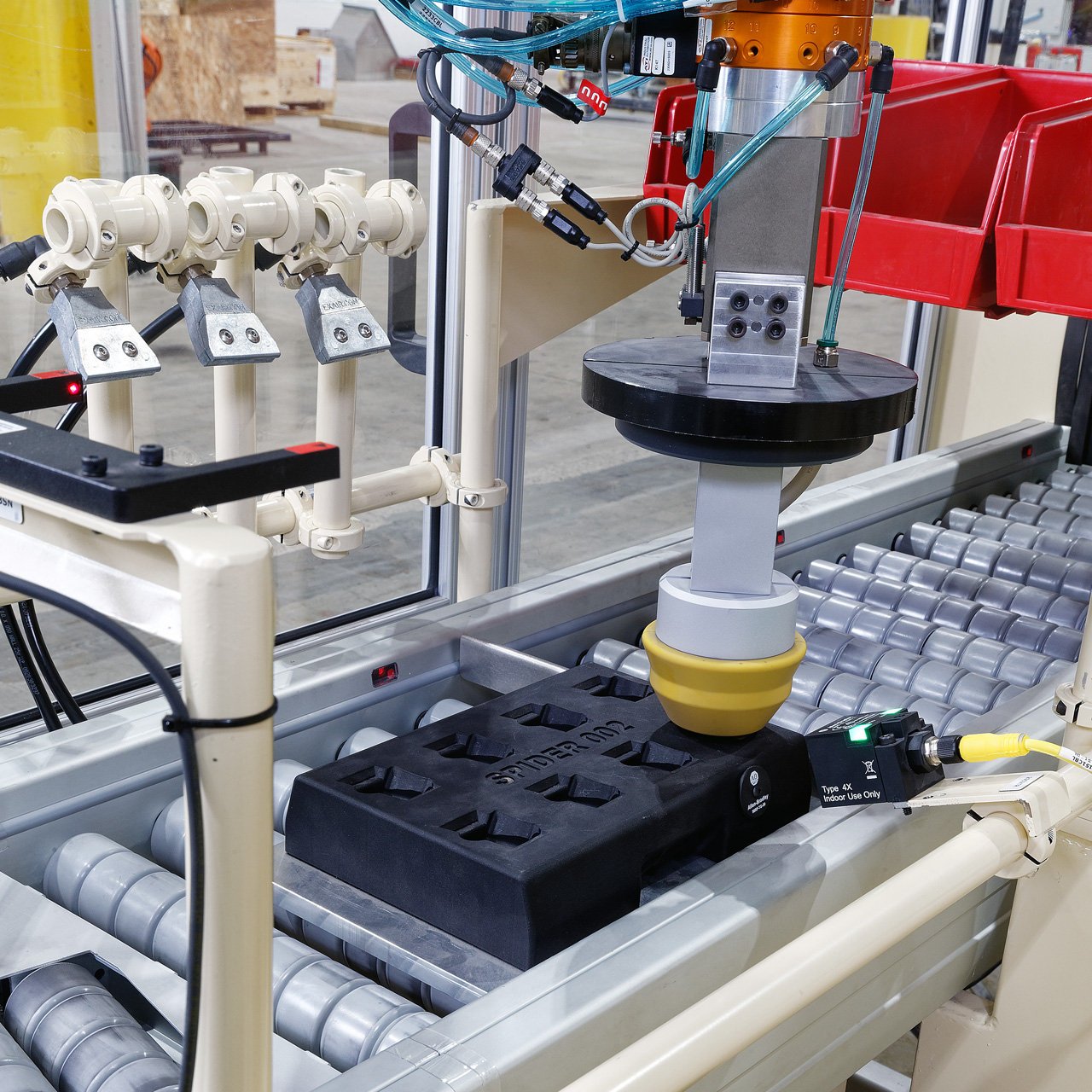

An RF tag reader identifies the part number on the incoming pallet. The robot automatically chooses the appropriate part gripper to pull the part and mask it for the airfoil grit blasting operation. The robot orients the part within the blast zone with its wrist motion while sealing against the cabinet wall. An array of six suction blast nozzles oscillate across the part to etch the surface.

- Robot pulls parts from the infeed conveyor and reaches 12 tool changer holsters

- Grippers are molded to the root form and protect it from the blasting process

- Large accumulating conveyors at the infeed and outfeed of the cabinet

- Durable nozzle oscillator performs reliably in the harsh process environment

- Media flow monitors

- Media classification sieve (optional)

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

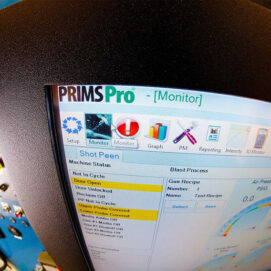

PRIMS Pro® Process Reporting and Integrated Monitoring System

Small Robotic Grit Blast with Manual Station

Fine Mesh Robotic Grit Blast with Drying Station