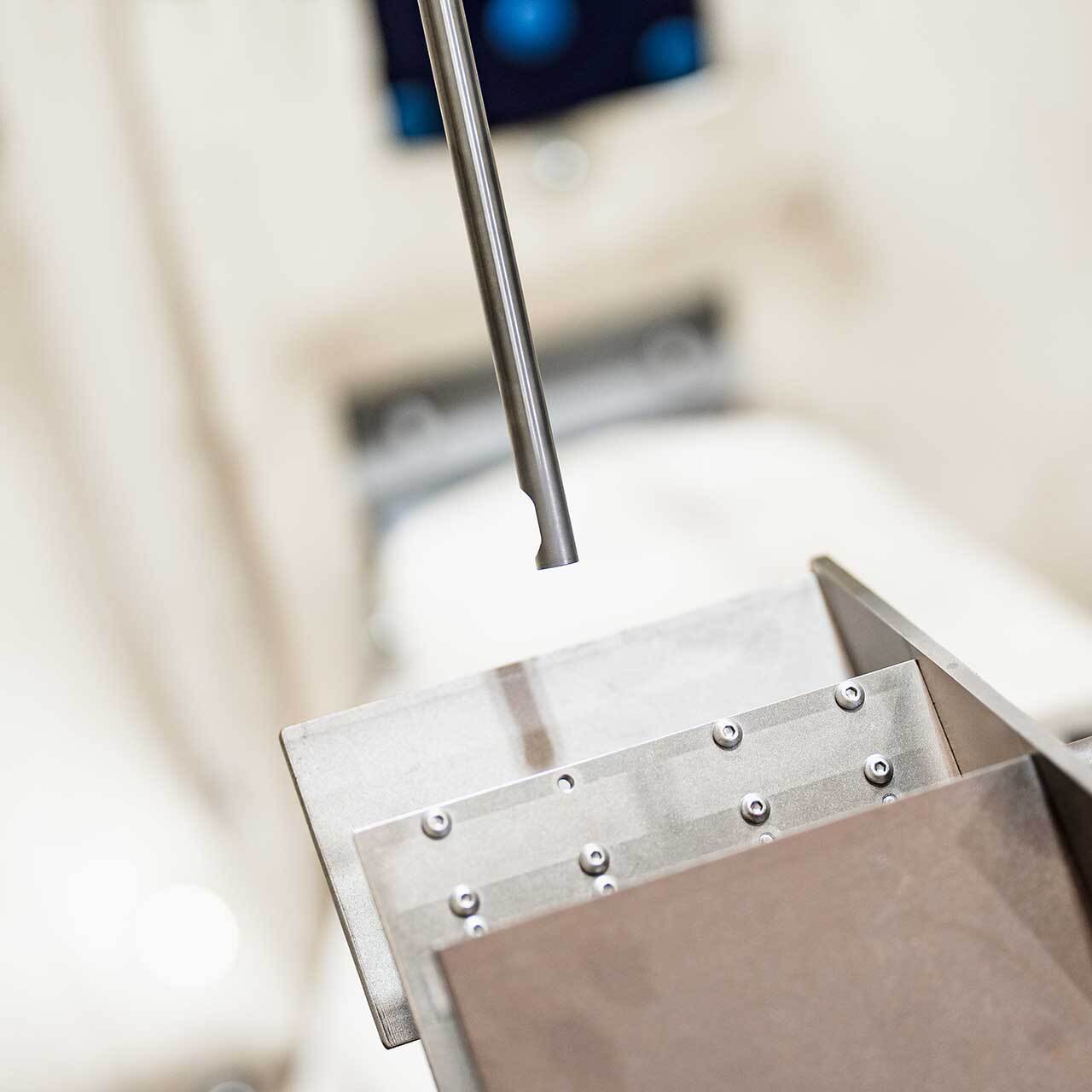

Shot Peening

Home / Shot Peening / Process Development Capabilities

Our unique combination of system engineering expertise, leading edge process development, and lifetime support, allow us to provide customers with the right solution to their processing needs.

Process Development Capabilities

Leverage our nearly 60 years of process and equipment design knowledge

Tell us your goals for a new or existing product, and we’ll help you select the process and develop the parameters to reach them. Our in-house collection of robotic machines enables us to explore various methods and repeat the results for demonstration. We’ll also look at multiple fixturing methods to minimize part-handling steps and reduce production cycle times. Our final report will detail our various tests, the tradeoffs discovered, and the final parameters that achieved the goal.

- Free initial discovery service benefits both Progressive Surface and the customer

- Progressive estimates cycle times and suggests machine configurations to achieve throughput

- Recommends materials to resist wear in harsh process environments

- Provides considerations for manual and automated part loading and unloading

Related Machines

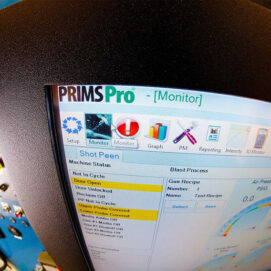

PRIMS Pro® Process Reporting and Integrated Monitoring System

Advanced, flexible process control for shot peening, grit blasting, and waterjet cleaning.

Read More

Torsion Bar Shot Peen System

Pivoting door design to quickly load parts for high-intensity shot peening.

Read More

Large Capacity Robotic Shot Peen with Multiple Media Sizes

Flexible system for peening critical rotating aircraft engine disks, spools, and shafts.

Read More

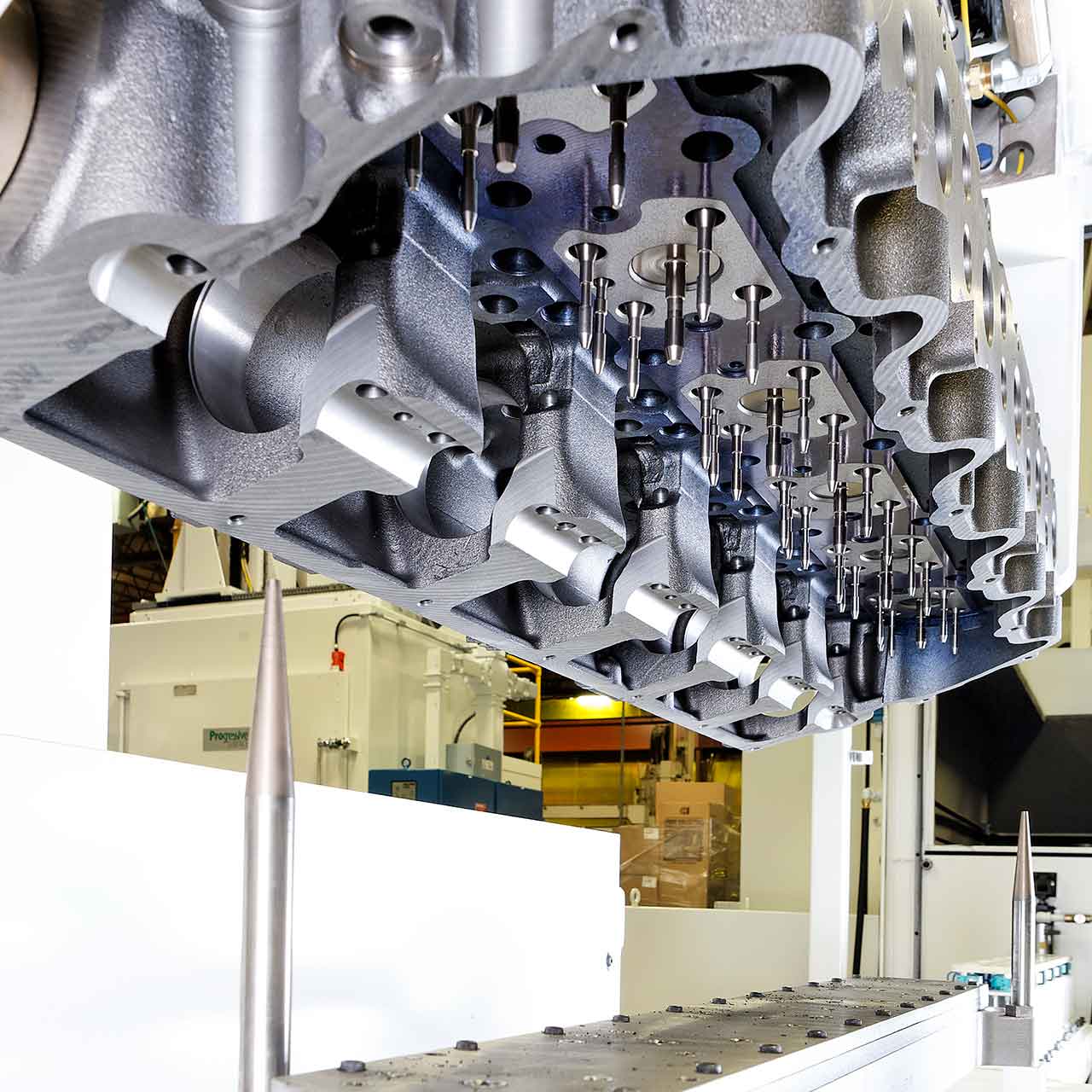

Automated Diesel Engine Head Shot Peen

High-volume peening for fatigue resistance with fully automatic part masking and loading.

Read More