Vertical Double Sided Aerospace Structures Shot Peen

Home / Shot Peening Videos / Vertical Double Sided Aerospace Structures Shot Peen

This is the first Vertical Structural Peening system for Progressive Surface. This unique peening system has an automated load and unload system so that parts can be fixtured in the first ‘peening frame’ while a second frame of parts is being peened by the machine. The monorail part manipulator lowers the parts to floor level where operators can load parts by hand or use the assistance of Positech load arms that service both load zones. One the part holding frame is loaded into the vestibule, the load door closes to seal in media and sound. The part is transferred to the peening zone and the gun mover stroke is controlled by the peening zone set by the operator in the PC based operator interface. The peening zones are set uniquely for each process cycle based on the combination of parts loaded into the frame. Two high-speed gun movers run the peening nozzles simultaneously across the front and back surfaces. The high speed movers enable the system to develop the peening stresses uniformly which is of critical importance to thin walled structures since part growth is a major quality consideration. When the peening process is finished, the part is fed back through the infeed vestibule where high volume air blowers remove residual peening media from pockets. There is also a manual peening station in the vestibule that allows for touch up. Since the parts must be held in the frames using special clamping tools, some surfaces will be masked on the first process pass. The operator is able to quickly move the fixtures and send the part through using a high speed touch-up program. The part is then returned to floor level for unloading.

Related Machines

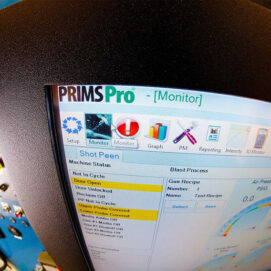

PRIMS Pro® Process Reporting and Integrated Monitoring System

Gantry Robotic Shot Peen System with Sliding Door

Heavy Duty Truck Transmission Gear Peen