Shot Peening

Home / Shot Peening / Automated Diesel Engine Head Shot Peen

Automated Diesel Engine Head Shot Peen

High-volume peening for fatigue resistance with fully automatic part masking and loading

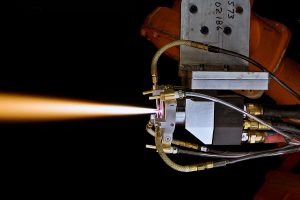

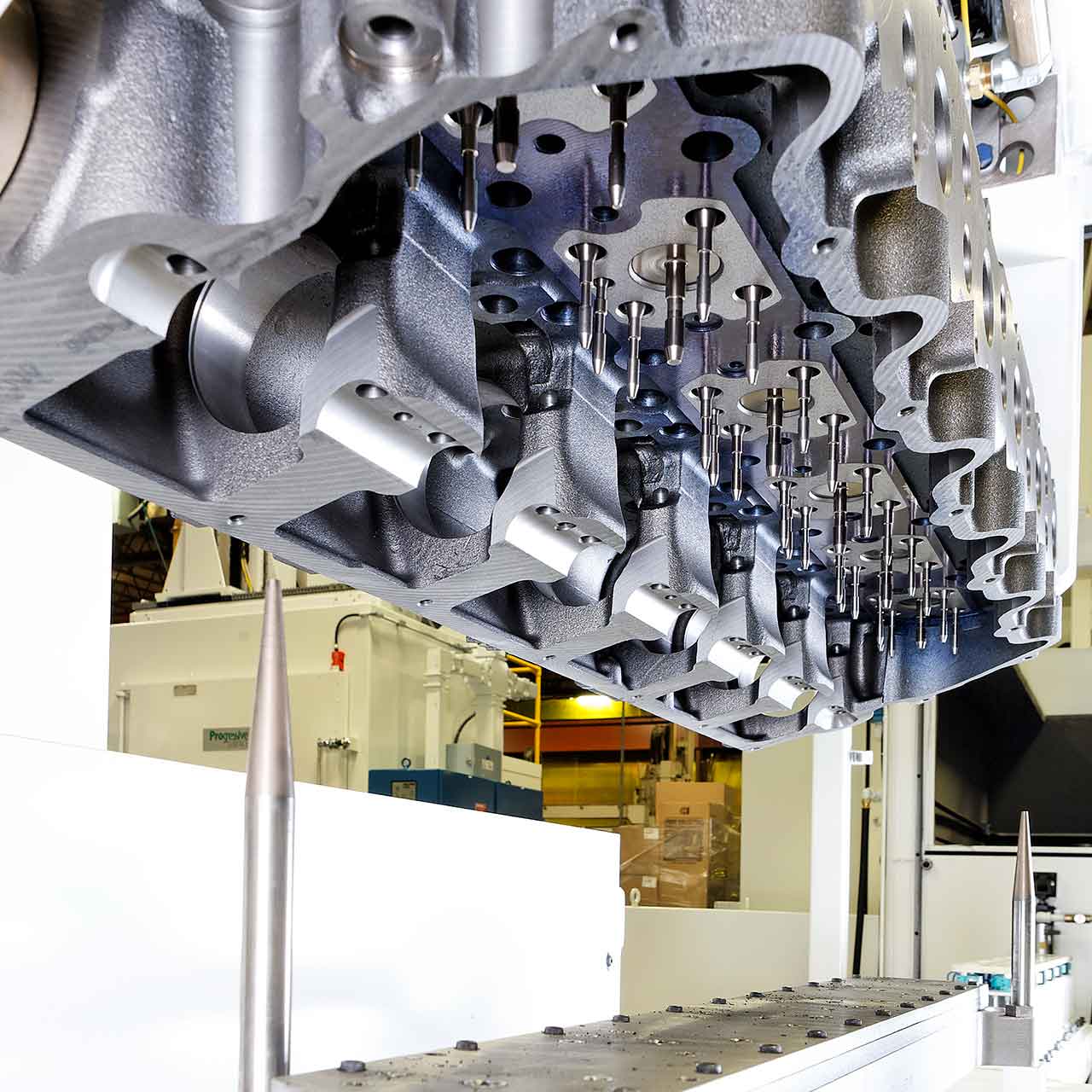

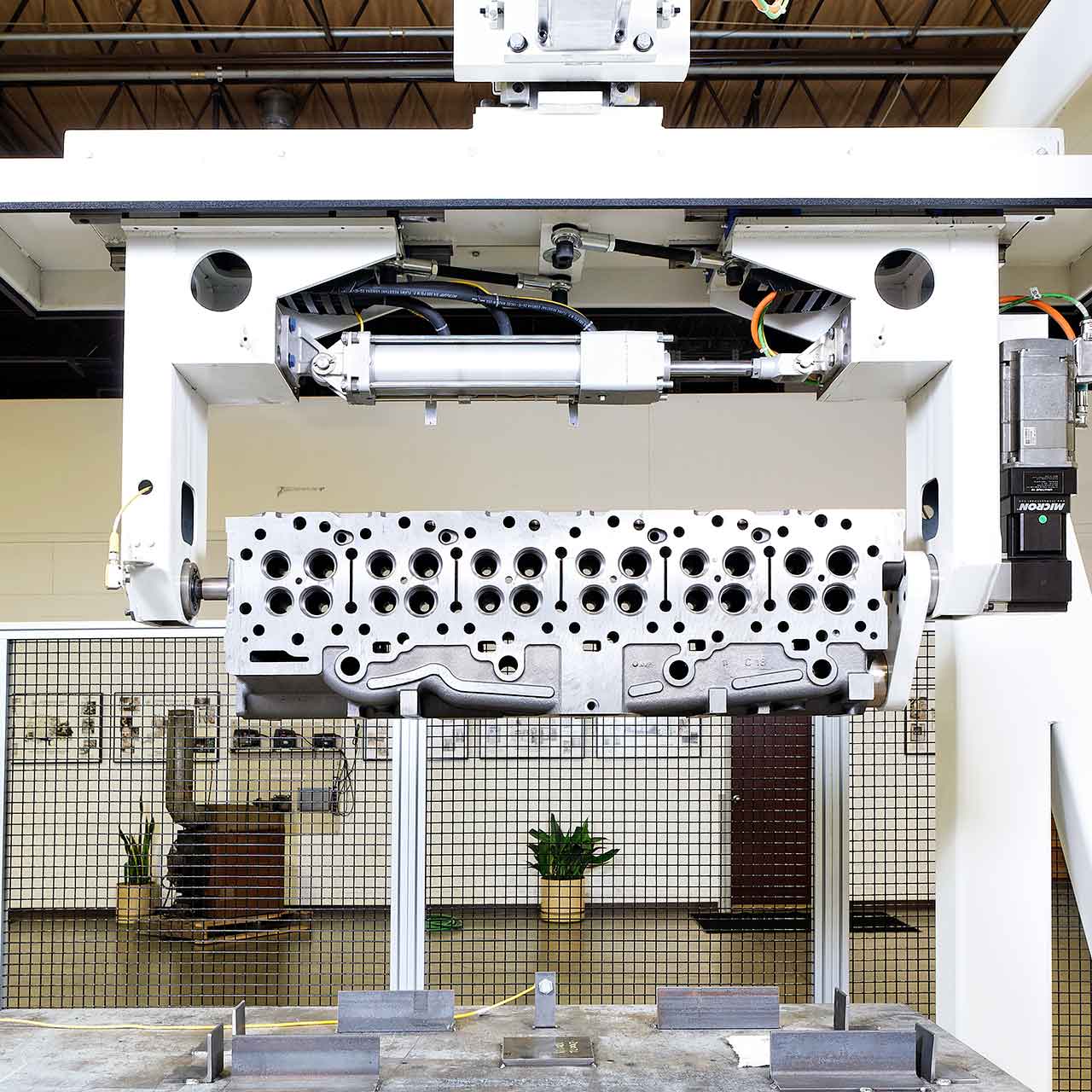

This system runs completely autonomously and is designed to mask and peen the cylinder areas on diesel engine heads. It uses an overhead gantry to pick, mask, check, and load diesel heads into the peening cabinet. Special pins mask off the valve and injector bores to prevent damage. Deflector pins redirect media from the nozzle to impinge on the inside surfaces of holes.

- Engine heads up to 44 inches by 14 inches by 10 inches tall

- Two axis nozzle manipulator for six pressure delivery nozzles

- The gantry transfers the head from the customer’s conveyor line through the peening cell and returns it to the line

- Siemens PLC and touchscreen operator interface

- Multi-year warranty (optional)

- Compressed air dryer (optional)

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

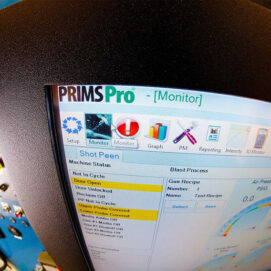

PRIMS Pro® Process Reporting and Integrated Monitoring System

Torsion Bar Shot Peen System

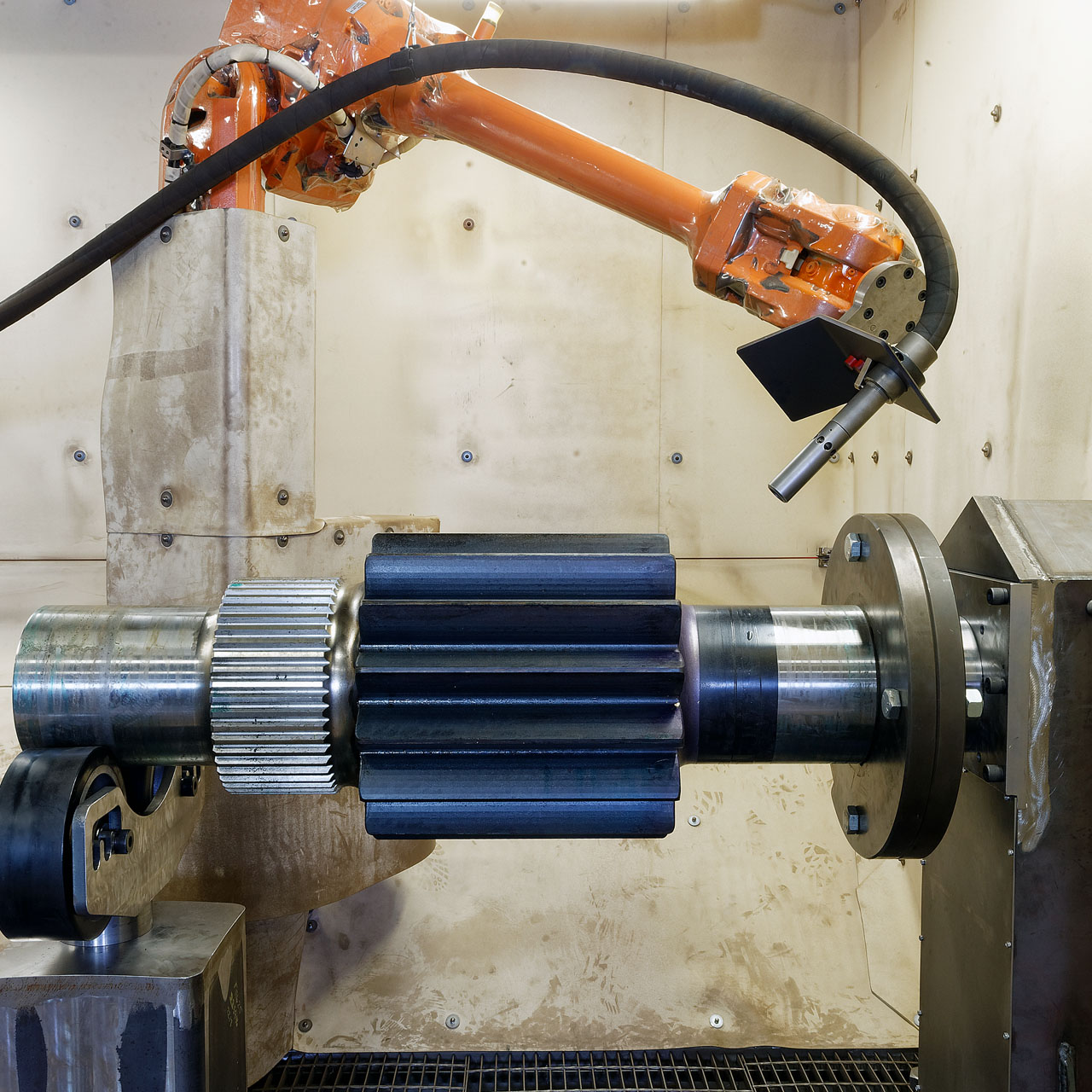

Gear Peening for Large Mining Equipment