Shot Peening

Home / Shot Peening / Large Auto Door Peening System with Tool Changer

Large Auto Door Peening System with Tool Changer

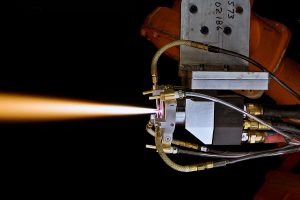

Robotic nozzle manipulation and tightest tolerance process parameter controls

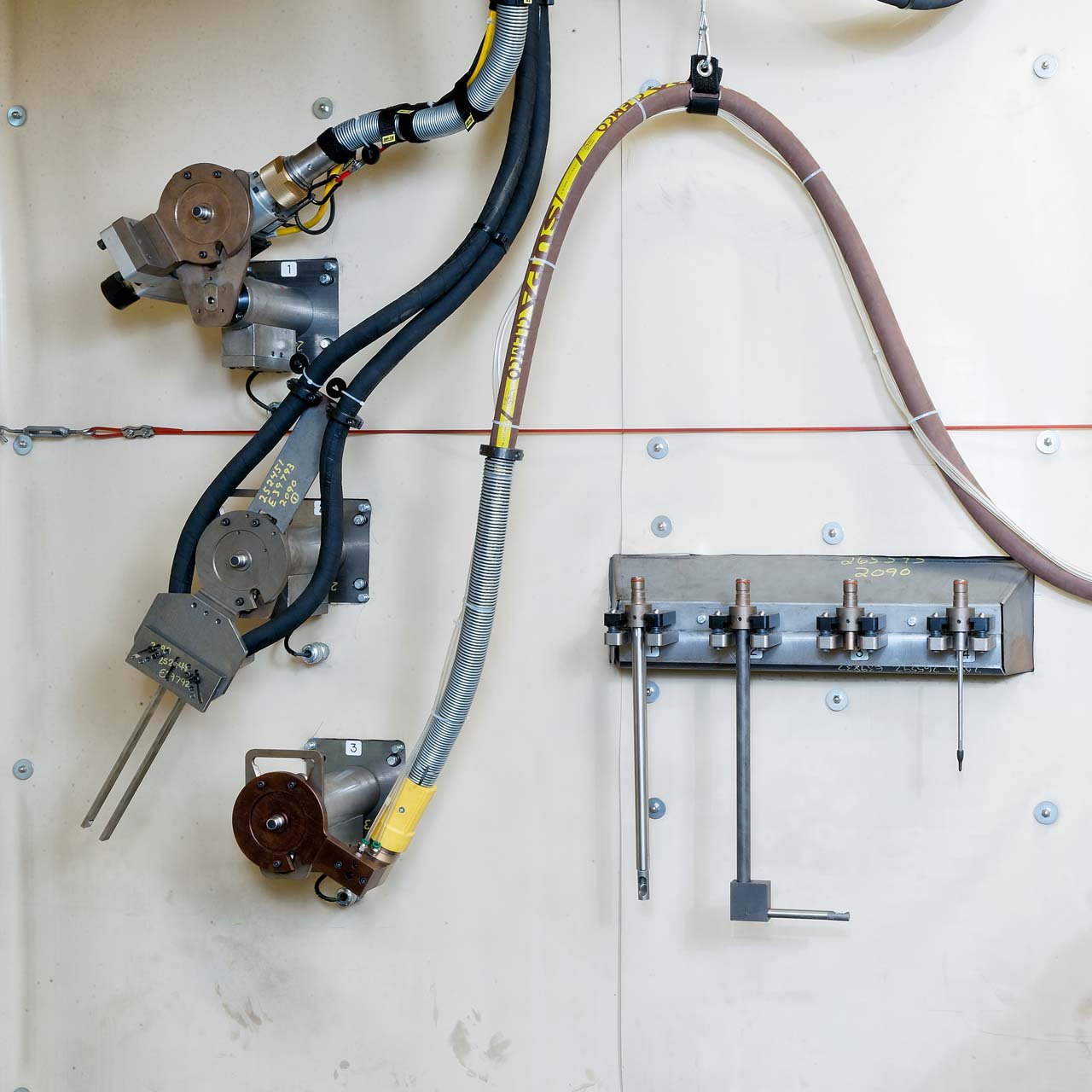

The peening environment presents challenges for creating and maintaining an accurate and repeatable system, especially when robotics and an automatic tool exchange system are incorporated. This system’s part program allows you to switch out the standard nozzle for a rotary lance device, double-opposing airfoil lances, or four deflector lances. Designed for the unique requirements of peening critical rotating aircraft engine parts.

- Parts up to 60 inches in diameter and 60 inches tall

- 1,000-pound capacity spindle with 68 inches of linear programmable stroke

- FANUC M710i robot with Foundry Pro Protection package and R-30i Controller

- Opposing dual-lance system for simultaneous peening of integrally bladed rotor airfoils

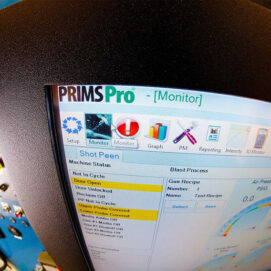

- PRIMS Pro® software provides ease of operation, continuous data collection, and report generation

- FANUC iRVision 2D integrated vision system (optional)

- Process development and part programming (optional)

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

PRIMS Pro® Process Reporting and Integrated Monitoring System

Compact Arm Robot Shot Peen Dual Spindle Table