Thermal Spraying

Home / Thermal Spraying / Automated Cell for Blade Tip Coating

Automated Cell for Blade Tip Coating

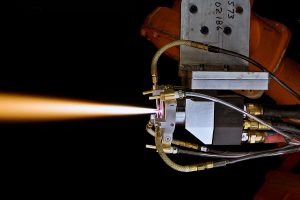

Large turbine blades are robotically handled through grit blast, plasma spray, and a finishing operation

Three different operations are integrated into one manufacturing cell. At the load station, the operator sets up the next part and arms the machine. A material handling robot moves the part and tooling to grit blast, plasma spray, and finishing operations. Each operation has robotic manipulation and integrated process controls. Part tracking and data logging are included.

- Four FANUC robots communicate with the cell leader

- 2D dot matrix reader on the robot records part number and serial number

- Pressure grit blast system features pressure pots, vibrator screener, and flow sensor

- Plasma spray system features two powder feeders and closed loop gas controls

- Part temperature sensing is integrated for preheat, coating, and cooling cycles

- Finish cell has servo spindle and abrasive wheels for coating overspray removal

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

CITS Pro® Computer Integrated Thermal Spray Systems

Robotic Plasma Spray Booth with Powder and Suspension Material Delivery

Robotic Multi-Process Thermal Spray System