Thermal Spraying

Home / Thermal Spraying / Suspension Plasma Spray for Aerospace

Suspension Plasma Spray for Aerospace

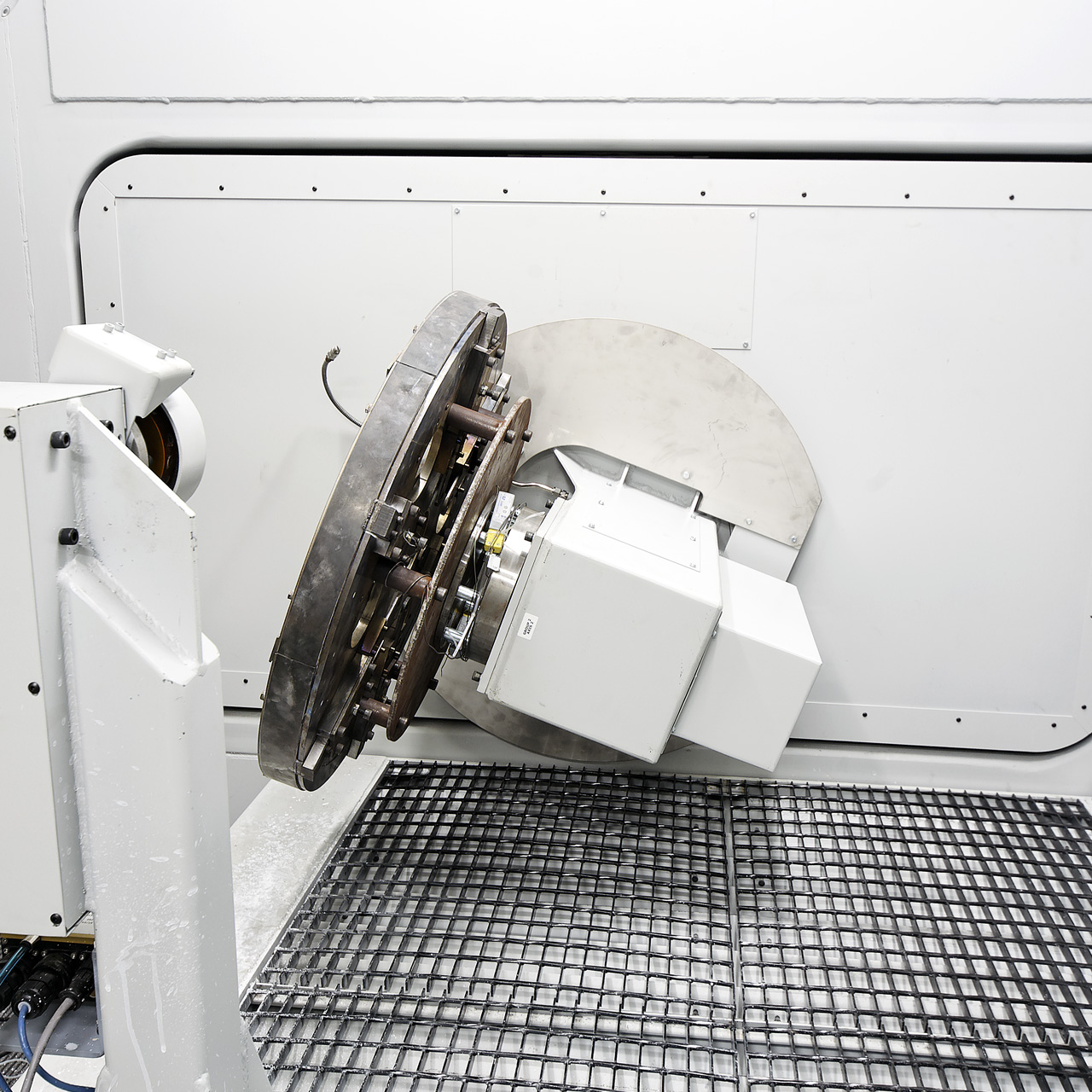

The double spindle enables part fixturing while in cycle with another part

This highly productive machine features side-by-side cabinets for spraying aircraft engine components. One spindle pivots into the cabinet while the other pivots out to the operator’s position. Sliding acoustical doors close over the load station to enable the exchange while the plasma torch is lit. The spindles can rotate about a vertical axis or tilt toward the robot arm for better targeting of complex geometries. The machine includes a slurry supply and recirculation system for ethanol-based slurries supplied in 400-gallon bulk totes.

- Pivoting spindles rotate parts up to 31 inches in diameter and 20 inches tall

- Spindles can pivot parts from 0 to 90 degrees in the part program

- Most plasma components are located on a mezzanine on the cabinet’s roof

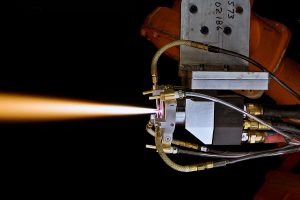

- Progressive Surface 100HE® plasma torch

- High-volume slurry supply and recirculation system (optional)

- Process viewing video camera with a monitor at the operator station (optional)

- Tecnar AccuraSpray integration (optional)

Related Machines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

CITS Pro® Computer Integrated Thermal Spray Systems

Robotic Plasma Spray Booth with Powder and Suspension Material Delivery

Robotic Multi-Process Thermal Spray System