Thermal Spraying

Our unique combination of system engineering expertise, leading edge process development, and lifetime support, allow us to provide customers with the right solution to their processing needs.

Thermal Spraying Machines

Process Development Capabilities

Leverage our nearly 60 years of process and equipment design knowledge.

Read More

CITS Pro® Computer Integrated Thermal Spray Systems

Process control, monitoring, and documentation for thermal spray.

Read More

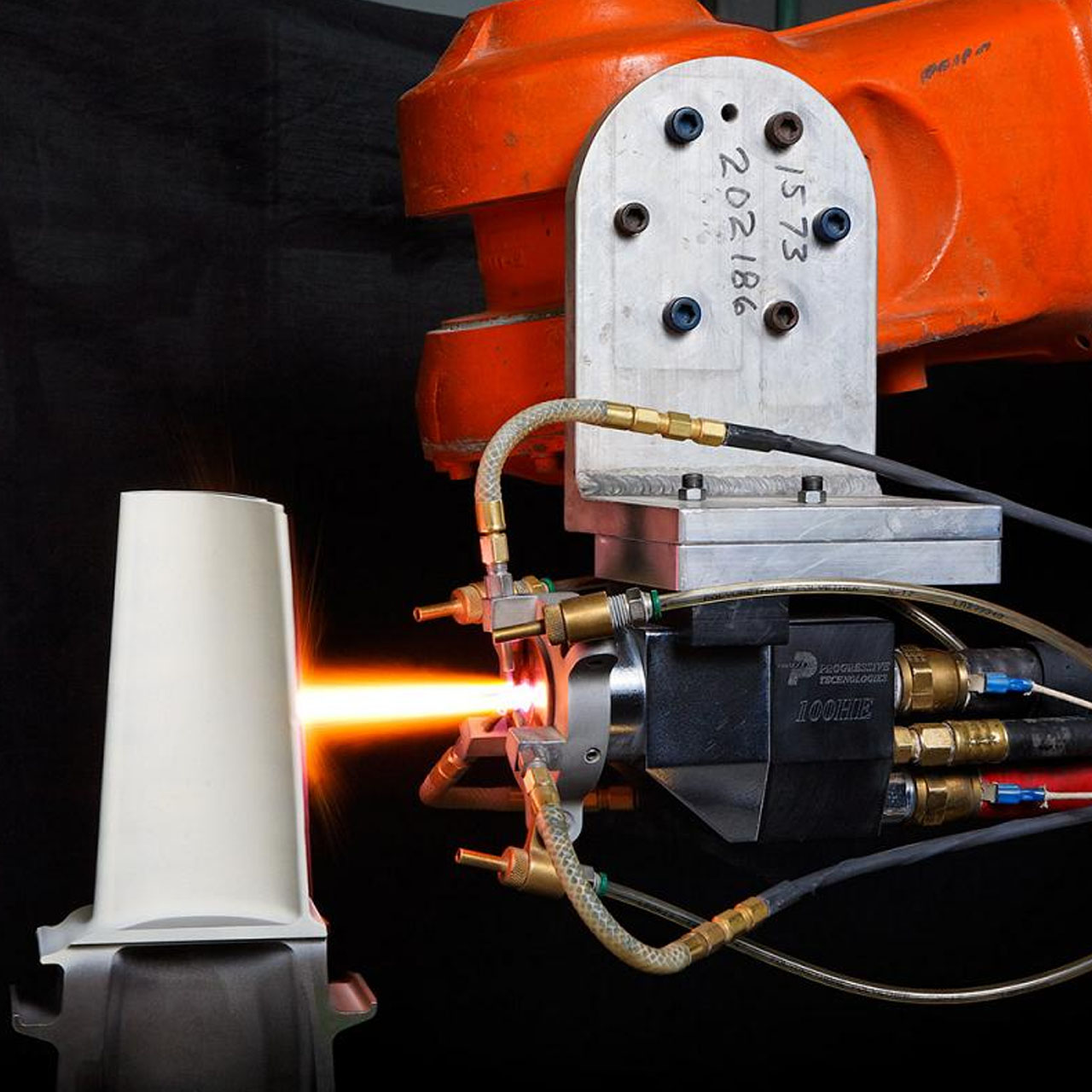

Robotic Plasma Spray Booth with Powder and Suspension Material Delivery

A truly Progressive plasma spray system with APS and SPS integration.

Read More

Robotic Multi-Process Thermal Spray System

Four plasma guns and an HVOF gun all run in this system with closed loop process controls.

Read More

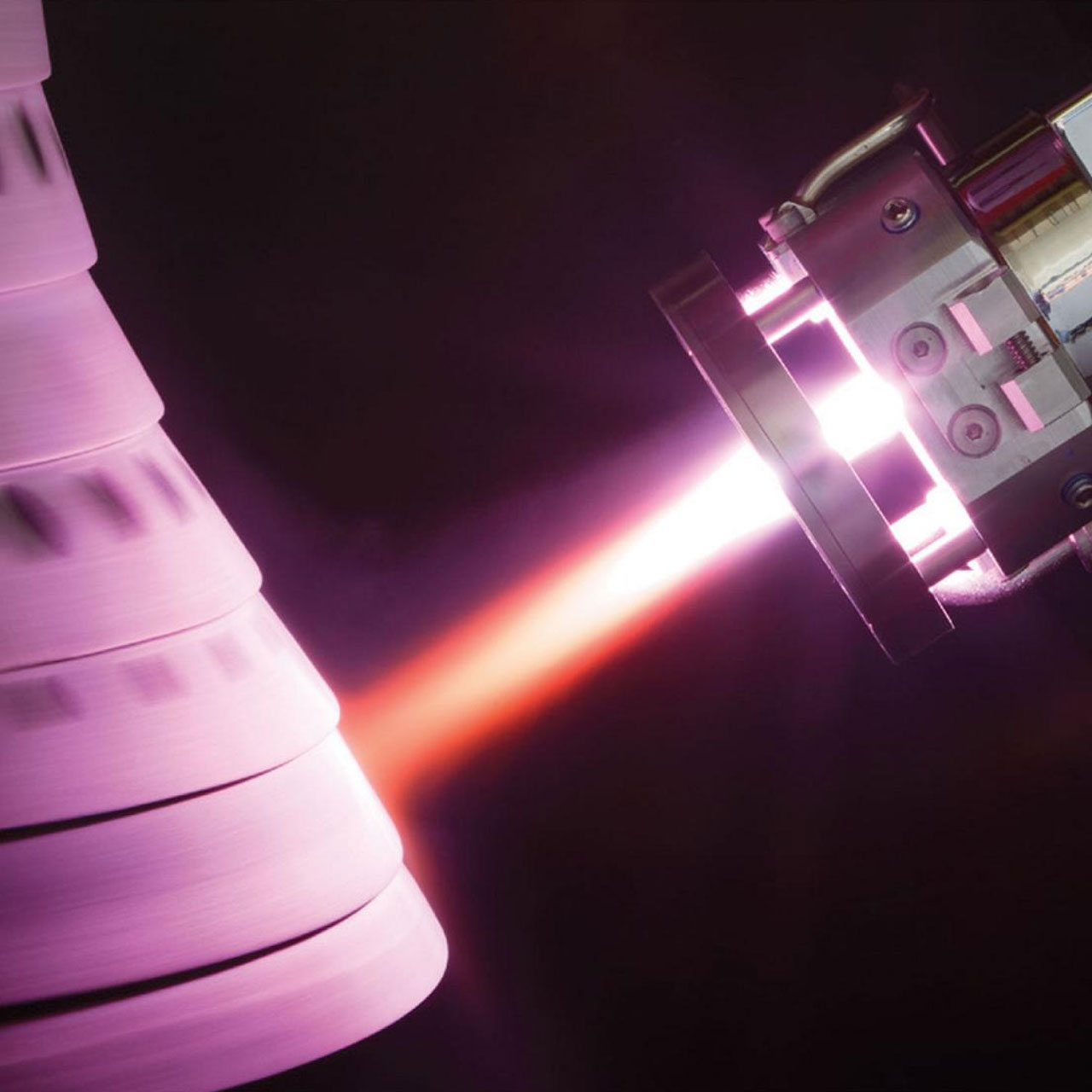

Suspension Plasma Spray for Aerospace

The double spindle enables part fixturing while in cycle with another part.

Read More

Suspension Plasma Spray Booths for Production

Robot moves plasma gun between two spray chambers, each with special work table and robotic cooling.

Read More

Large Crank Shaft HVOF Coating System

Purpose-built handling system moves crankshafts between the grit blast booth and HVOF coating booth.

Read More

Automated Cell for Blade Tip Coating

Large turbine blades are robotically handled through grit blast, plasma spray, and a finishing operation.

Read More

Robotic Argon Atmosphere Thermal Spray with Airlock Exchange

Plasma spray booth eliminates oxygen without a vacuum.

Read More

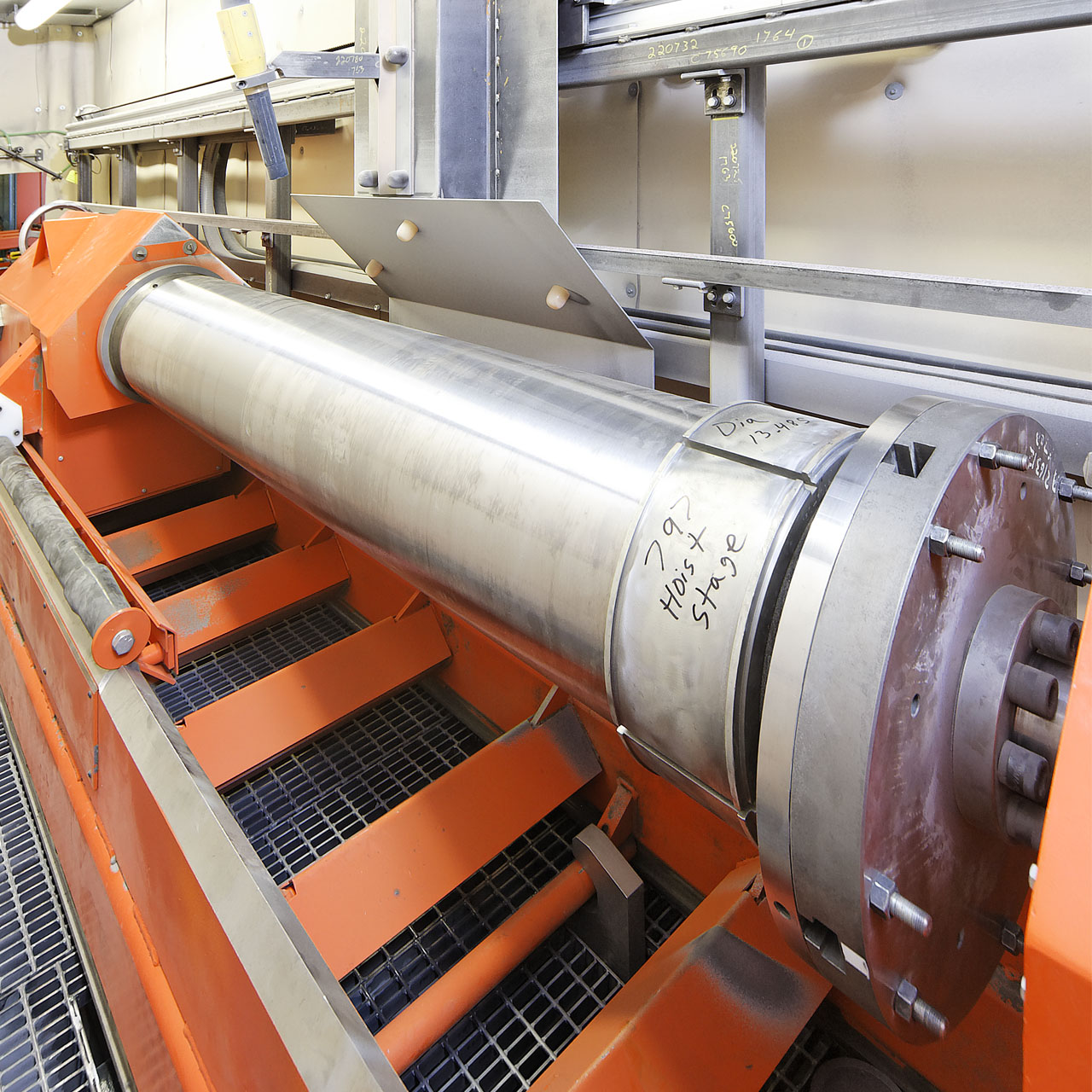

Large Lathe HVOF Spray Cell with Sliding Roof

Easy loading of heavy parts by overhead crane.

Read More

Hydraulic Rod Grit Blast and HVOF Spray

Parts on special lathe move to 2-axis systems for grit blast operation and HVOF coating operation.

Read More

Small Lathe HVOF Spray Landing Gear Components

Flexibility to run a wide variety of part geometries.

Read More