Anti-Fretting Cu-Ni-In Coating Removal System

Home / Waterjet Cleaning Videos / Anti-Fretting Cu-Ni-In Coating Removal System

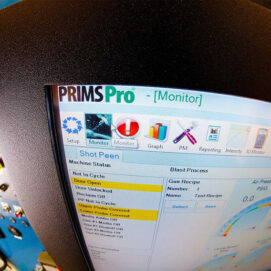

This unique system is designed to remove galling and fretting protection coatings from aircraft engine compressor section blade root pressure faces in high volume production. The machine utilizes an automated shuttle exchange for easy operator load and unload. The Progressive Surface PRIMS Pro operator interface simplifies the operation of the Fanuc based nozzle manipulator. The system ramps down pressure and parks the nozzle at a safe location to enable fixture exchange without full ramp-down/ramp-up of the intensifier pump improving efficiency.

Related Machines

PRIMS Pro® Process Reporting and Integrated Monitoring System

Advanced, flexible process control for shot peening, grit blasting, and waterjet cleaning.

Read More

48″ Diameter Ultra High Pressure Waterjet Stripping System

Quick return on investment by eliminating chemicals in aerospace MRO.

Read More

80″ Diameter Ultra High Pressure Waterjet Stripping System

Large envelope and high-capacity filter system for aerospace abradable coatings.

Read More

Large Diameter Ultra High Pressure Waterjet Stripping System

Sliding automatic double doors save on floor space.

Read More